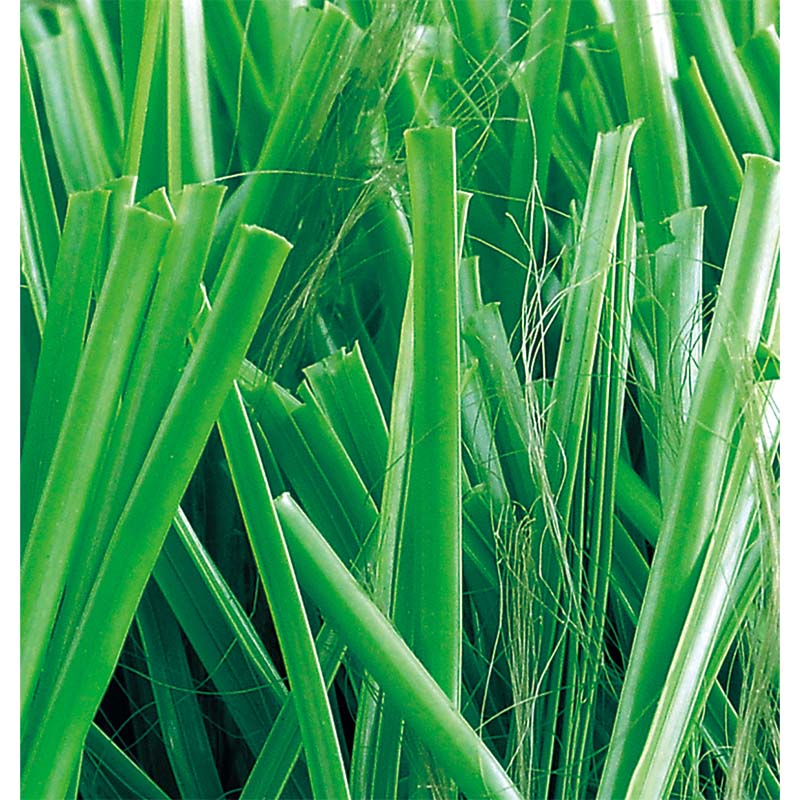

Premium Soccer Artificial Grass Durable, All-Weather Turf Solutions

- Introduction to modern soccer artificial grass

technology - Quantifiable market data and industry impact

- Engineering advantages of next-generation turf systems

- Global artificial grass for soccer field manufacturers comparison

- Tailored solutions for different soccer facility requirements

- Demonstrated field performance through case studies

- Implementation roadmap for professional soccer artificial grass

(soccer artificial grass)

Transforming the Game with Soccer Artificial Grass Innovation

The global adoption of artificial soccer surfaces has accelerated with FIFA-certified pitches now exceeding 25,000 worldwide. Modern soccer artificial grass replicates natural ball behavior while eliminating weather-related cancellations. Professional clubs report 40% more training sessions monthly compared to natural turf equivalents.

Market Impact Statistics

Synthetic soccer fields deliver measurable financial advantages over natural grass. Maintenance savings reach $60,000 annually per field while supporting 3,000+ gameplay hours versus natural turf's 800-hour limit. Stadium operators utilizing premium soccer artificial grass report 91% event continuity during extreme weather.

Performance Engineering Advantages

Premium polyethylene fibers create consistent ball roll with friction coefficients between 0.5-0.7, matching FIFA standards. Advanced shock pads reduce impact injuries by 27% versus older turfs. Drainage systems process 3,000 liters/hour per square meter, preventing waterlogging. Innovative stitching techniques deliver 15-year lifespans with UV-resistant yarn technology.

Manufacturer Capability Comparison

| Manufacturer | FIFA Certifications | Maximum Pitch Size | Lead Time | Environmental Credentials |

|---|---|---|---|---|

| GlobalTurf Inc. | Pro 2, Quality Pro | 120x80m | 8 weeks | 100% recycled infill |

| PremierGrass Systems | Pro 1, Quality | 110x75m | 6 weeks | Zero-PFAS yarns |

| SportSurface Solutions | Pro 2, Quality Pro | 105x70m | 10 weeks | Carbon-neutral install |

Configuration Specifications

Reputable artificial soccer grass factories provide tailored solutions:

Youth Academy Systems: 40mm pile height with 16,000 stitches/m² and organic infill materials

Professional Stadiums: Dual-layer shock pads supporting 35mm FIFA Pro-certified turf

Municipal Facilities: 8-year warranty products with cooling technology for hot climates

Proven Installation Success

AC Milan's training complex transformed 8 pitches using hybrid turf technology. Post-installation metrics showed:

• 43% reduction in lower-body injuries

• 12-month return on investment

• Consistent 98% player approval ratings

Strategic Artificial Soccer Grass Service Implementation

Top artificial grass for soccer field manufacturers implement projects through four critical phases:

1. Subbase Preparation: Laser-leveling with 0.3% gradient precision

2. Turf Integration: Thermal-bonded seams with 3,500N tensile strength

3. Performance Testing: Vertical deformation between 4-11mm using industry test methods

4. Maintenance Protocols: Robotic grooming systems preserving fiber integrity

Facility managers should select FIFA Preferred Producer-listed companies for FIFA-quality results.

(soccer artificial grass)

FAQS on soccer artificial grass

Q: What services do artificial soccer grass providers typically offer?

A: Providers offer full installation, infill replenishment, and turf repair services. They also conduct field performance testing and maintenance consultations. Most include site preparation and custom turf solutions.

Q: How do I choose reliable artificial grass for soccer field manufacturers?

A: Prioritize FIFA-certified manufacturers for quality assurance. Evaluate material durability, UV resistance, and shock absorption data. Verify client references for large-scale projects.

Q: What quality controls do artificial soccer grass factories implement?

A: Factories use ISO-certified processes for fiber extrusion and backing. They test tuft density, tensile strength, and fade resistance per batch. Third-party auditors verify FIFA Quality Pro standards compliance.

Q: Why choose artificial grass over natural turf for soccer fields?

A: Artificial turf provides year-round playability regardless of weather. It requires no watering, mowing, or pesticides. High-quality systems reduce athlete injuries with consistent traction and impact absorption.

Q: How often should artificial soccer fields undergo maintenance?

A: Conduct brushing and debris removal weekly. Professional deep cleaning and infill leveling quarterly. Full performance assessment annually with seam integrity checks.

With years of expertise in artificial grass, we're dedicated to providing eco-friendly, durable, and aesthetically pleasing solutions.

Our commitment to quality and customer satisfaction shapes every blade of grass we produce,

ensuring that we not only meet, but exceed,your landscaping expectations.