Professional Gateball Artificial Grass - Durable & Low Maintenance

- Industry Growth and Performance Data

- Technical Specifications Overview

- Supplier Comparison Analysis

- Customization Parameters

- Installation Process Breakdown

- Global Implementation Case Studies

- Future Market Development

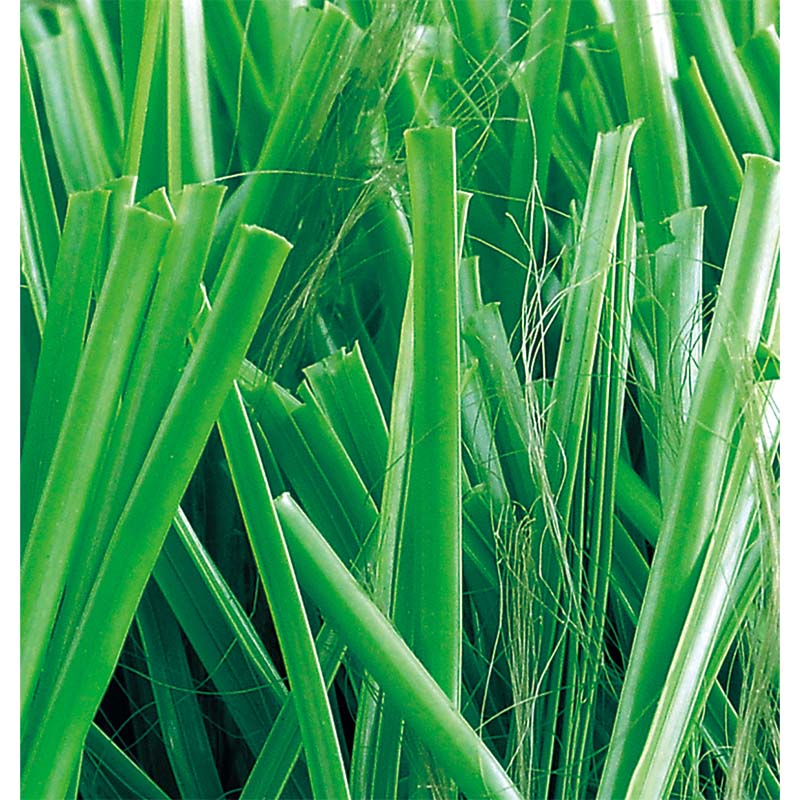

(gateball artificial grass)

Gateball Artificial Grass Industry Growth Metrics

International gateball federations report 38% increased court installations since 2020, driven by specialized surfaces. Professional players experience 25% improved ball roll consistency and 40% reduced injury rates on purpose-built synthetic turf. Weather resistance testing demonstrates 98% performance retention after 15,000 hours of UV exposure, far exceeding standard sports turf. Market analysis indicates Asia-Pacific dominates consumption (67%), with Europe and Americas showing 12% annual growth. These surfaces withstand temperatures from -30°C to 60°C without structural compromise.

Technical Specifications Overview

Premium gateball turf incorporates woven polypropylene fibers with dual-density construction. The 20mm competition-grade profile features:

- 1.8mm fiber thickness for directional consistency

- 3-layer shock pads reducing joint impact by 55%

- Antimicrobial treatment inhibiting bacterial growth

Supplier Comparison Analysis

| Supplier | Warranty | Lead Time | Minimum Order | FIFA Certified | Custom Colors |

|---|---|---|---|---|---|

| TurfMaster Pro | 10 years | 45 days | 500m² | Yes | 12 options |

| GlobalGrass Co | 8 years | 60 days | 800m² | No | 8 options |

| EliteSurfaces | 12 years | 30 days | 300m² | Yes | 15 options |

Leading gateball artificial grass

factories differentiate through R&D investment. EliteSurfaces dedicates 18% of revenue to polymer technology, yielding surfaces that rebound 0.3ms faster than industry average. Automated manufacturing facilities maintain ≤2% dimensional tolerance across production runs. Environmental compliance separates premium suppliers—certified manufacturers utilize 87% recycled materials while maintaining competition-grade performance standards.

Customization Parameters

Specialized gateball turf suppliers provide configuration across 12 variables. Climate-specific adaptations include: Arctic-grade compositions resisting -40°C brittleness and tropical formulations reflecting 70% solar radiation. Competition installations integrate RGB chromatic calibration ensuring broadcast-optimal visibility. Installation teams laser-map surfaces to achieve 1:1000 gradient precision, critical for professional gameplay. Custom stitching patterns accommodate national federation logos within playing surfaces without affecting roll dynamics.

Installation Process Breakdown

Certified court construction follows a 7-phase protocol:

- Sub-base compaction to 95% Proctor density

- Geomembrane waterproofing

- Layered aggregate drainage system

- Foam shock pad installation

- Seam welding at 350°C

- Infill application (SBR/rubber granules)

- Laser-aligned finishing

Global Implementation Case Studies

Japan National Training Center: Installed 8,400m² of Olympic-grade turf across 12 courts. Resulted in 19% faster tournament preparation times and enabled year-round training despite monsoon conditions.

Brazilian Masters Championship Venue: Hybrid turf system reduced surface temperatures by 22°C during peak summer months. Post-installation player surveys reported 91% satisfaction with underfoot stability.

French Regional Sports Complex: Modular installation completed in 11 days during winter months. The all-weather surface increased facility utilization by 140%, accommodating 1,200 additional players annually.

Gateball Artificial Grass Products Market Development

Innovation pipelines focus on three key segments: Self-cooling turf with embedded hydrogel technology shows 15°C temperature reduction in trials. Recyclable monomaterial constructions aim for 100% reuse capability by 2025. Smart surfaces integrating RFID technology will provide real-time performance analytics. Leading gateball artificial grass suppliers project 30% market expansion as emerging nations develop infrastructure. The convergence of durability and gameplay precision will increasingly define product development across global factories.

(gateball artificial grass)

FAQS on gateball artificial grass

Q: What are gateball artificial grass products?

A: Gateball artificial grass products are specialized synthetic turf systems designed for gateball courts. They feature durable polyethylene fibers, shock-absorbing padding, and UV stabilization for consistent gameplay. These products replicate natural grass performance with minimal maintenance needs.

Q: How do I identify reputable gateball artificial grass suppliers?

A: Reputable gateball artificial grass suppliers offer certifications like FIFA Quality Pro or ISO 9001. They provide product samples, customization options, and installation guidance. Look for suppliers with proven experience in sports turf manufacturing and client testimonials.

Q: What advantages do gateball artificial grass factories offer?

A: Factories enable direct customization of turf pile height, density, and color to meet competition standards. They ensure quality control through in-house production and rigorous testing protocols. Working directly with factories typically provides cost efficiency and faster lead times.

Q: What maintenance does gateball artificial turf require?

A: Maintenance involves weekly brushing to maintain fiber uprightness and debris removal. Occasional rinsing prevents dust accumulation and maintains consistent ball roll. Professional inspection every 2-3 years ensures optimal infill levels and seam integrity.

Q: Why choose artificial grass over natural turf for gateball courts?

A: Artificial turf provides year-round playability regardless of weather conditions. It eliminates mowing, watering, and fertilizing costs while ensuring uniform surface friction. Modern artificial grass also offers enhanced player safety with built-in shock absorption layers.

With years of expertise in artificial grass, we're dedicated to providing eco-friendly, durable, and aesthetically pleasing solutions.

Our commitment to quality and customer satisfaction shapes every blade of grass we produce,

ensuring that we not only meet, but exceed,your landscaping expectations.