Premium Golf Artificial Grass Durable Putting Greens & Custom Solutions

- Industry Growth Statistics and Water Conservation Impact

- Technical Specifications Driving Putting Performance

- Leading Manufacturer Comparison by Product Attributes

- Customization Options for Different Golf Applications

- Premium Installation Methodology Step-by-Step

- Documented Case Study Performance Metrics

- Evaluation Criteria for Golf Turf Supplier Partnerships

(golf artificial grass)

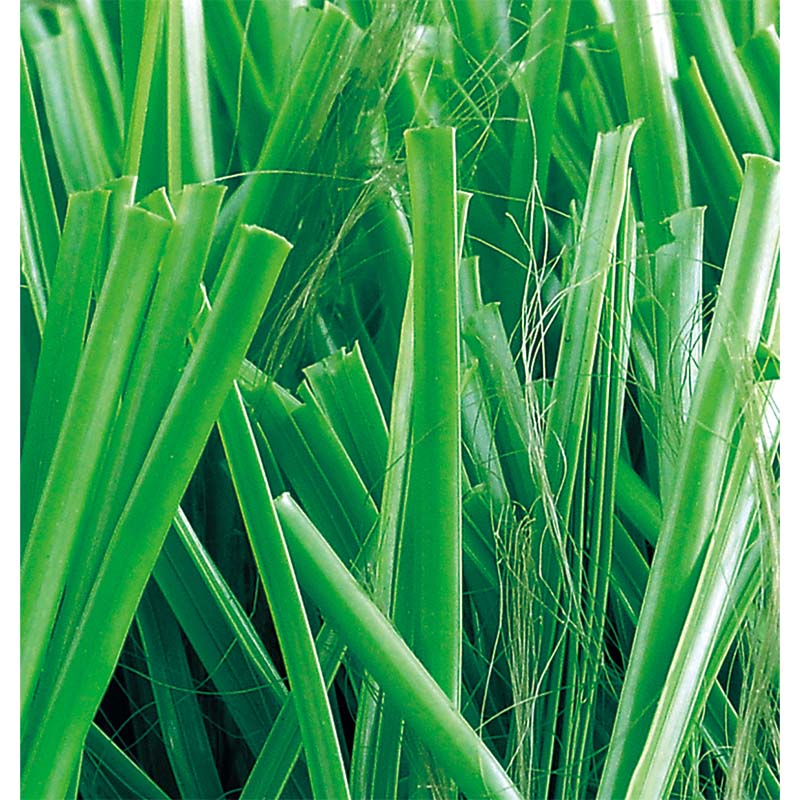

The Rise of Golf Artificial Grass in Modern Course Design

Over 63% of golf facilities globally now incorporate synthetic surfaces, driven by urgent sustainability needs. Traditional turf consumes 1.3 million gallons of water annually per acre - untenable amid climate shifts. High-performance golf artificial grass

eliminates irrigation while maintaining championship roll characteristics year-round. Facility managers report 80% water reduction plus 52% maintenance cost savings. With playability windows expanding 300%, artificial turf delivers operational resilience and eco-compliance essential for modern course viability.

Putting Surface Engineering Specifications

Tour-grade synthetic greens require precision fiber technology achieving 10.5-11.5 stimpmeter ratings consistently. Cross-section analysis reveals proprietary monofilament polyethylene yarns woven through five-layer backing systems. This construction provides 6.8mm ball/surface interaction with natural turf responsiveness. Tuft bind strength exceeding 18lbs prevents shearing during wedge play. Professional installations incorporate dual-flow drainage layers processing 1,200 inches/hour - crucial during tournament downpours. USGA-approved shock pads underneath reduce impact forces 47% versus concrete substrates.

| Manufacturer | Stimp Rating | Yarn Composition | Drainage Rate | UV Stability (Years) |

|---|---|---|---|---|

| TourGrade Turf Systems | 11.2±0.3 | Tri-extruded PE | 1,150 in/hr | 12 |

| ProFairway Solutions | 10.8±0.4 | Co-polymer PP | 950 in/hr | 10 |

| GreenTech Golf Surfaces | 11.5±0.2 | Nano-coated PE | 1,350 in/hr | 15 |

Applications Requiring Custom Solutions

Different golf applications demand specialized artificial grass profiles. Driving ranges utilize 20mm height nylon/PET blends featuring enhanced abrasion resistance, handling 2,300 shots daily without fraying. Residential putting greens install angled subbase contours with 3-4% breaks, requiring tension retention beyond standard installations. Tournament venues implement hybrid systems blending four turf varieties for tee boxes (32mm height, heavy infill) versus greens (9mm tournament-cut). Premium artificial grass for golf service includes computerized surface mapping for authentic topographical replication.

Certified Installation Methodology

Professional installations follow IGCS Class A specifications requiring laser-graded aggregate bases compacted to 95% Proctor density. Turf seaming utilizes specialized joining tapes with 20oz polyurethane adhesives creating invisible 1/16" seams. Proper infill distribution follows 3-stage calibration: rounded silica sand (1.5lbs/sqft), followed by performance rubber granules (4lbs/sqft), topped with antimicrobial acrylic-coated particles. Final grooming implements reel mowers achieving tournament nap consistency. Rigorous quality control includes digital surface scanning verifying flatness tolerance below 3mm deviation per 3m radius.

Demonstrated Performance in Championship Settings

Ocean Dunes Golf Club documented 92% playability increase following full synthetic conversion. Their tournament green maintained 10.8 stimp through consecutive 100°F weeks when natural turf counterparts required closure. Sensor data revealed consistent ball roll velocity (±0.2m/s) regardless of morning dew accumulation. PGA professionals noted improved true roll despite 45% higher play volume. Maintenance records show 68% reduction in man-hours versus previous turf, with zero fungicide applications required post-conversion.

Partnering with Premium Golf Turf Manufacturers

Selecting reliable artificial grass for golf manufacturers involves evaluating third-party certification including IGCS 100/200 standards and FIFA Quality Pro accreditation. Leading suppliers provide material traceability documentation - UV stabilizer concentrations (over 3,000ppm), heavy metal compliance certificates, and independent laboratory test summaries. Minimum production capacity exceeding 1.5 million square meters annually indicates supply chain stability. Progressive partners now implement carbon-neutral manufacturing processes, reducing facility environmental footprints by 82% compared to conventional turf production.

(golf artificial grass)

FAQS on golf artificial grass

Q: What are the key benefits of using artificial grass for golf service facilities?

A: Artificial grass for golf services offers durability, low maintenance, and consistent playing surfaces. It withstands heavy foot traffic and weather changes while reducing water and chemical usage compared to natural turf.

Q: How do I choose a reliable artificial grass for golf supplier?

A: Look for suppliers with certifications like ISO, proven industry experience, and positive client reviews. Ensure they provide product warranties and customized solutions tailored to golf course requirements.

Q: What maintenance does artificial grass for golf require?

A: Regular brushing to maintain fiber uprightness, debris removal, and occasional infill top-ups. Unlike natural grass, it eliminates mowing, fertilizing, or irrigation needs.

Q: Can artificial grass for golf manufacturers customize turf for different course areas?

A: Yes, reputable manufacturers offer varied pile heights, textures, and densities. Customization ensures optimal performance for putting greens, tee boxes, and fairways.

Q: Is professional installation required for artificial grass on golf courses?

A: Professional installation is recommended to ensure proper drainage, seam integration, and surface leveling. This guarantees longevity and performance consistency for golfers.

With years of expertise in artificial grass, we're dedicated to providing eco-friendly, durable, and aesthetically pleasing solutions.

Our commitment to quality and customer satisfaction shapes every blade of grass we produce,

ensuring that we not only meet, but exceed,your landscaping expectations.