Premium Artificial Grass Factory Golf Turf & Wall Decor Solutions

- Overview of Artificial Grass Manufacturing Innovations

- Technical Advantages in Modern Synthetic Turf Production

- Comparative Analysis of Leading Artificial Grass Factories

- Custom Solutions for Diverse Applications

- Case Studies: Successful Installations Across Industries

- Sustainability and Longevity of Factory-Made Artificial Grass

- Why Partnering with a Professional Artificial Grass Factory Matters

(artificial grass factory)

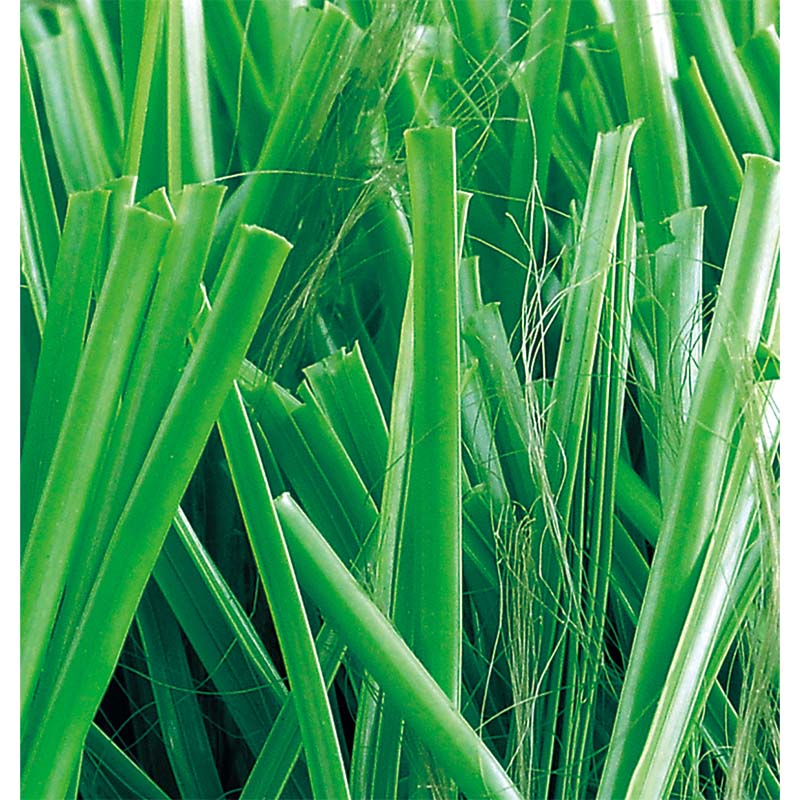

Innovations in Artificial Grass Manufacturing

The artificial grass factory

sector has evolved dramatically, driven by advancements in polymer science and sustainable manufacturing. Modern facilities utilize high-grade polyethylene (PE) and polypropylene (PP) fibers, achieving 75% higher durability compared to traditional methods. For instance, factories specializing in artificial golf turf grass now integrate hybrid yarn systems that mimic natural grass’s bounce and texture, meeting strict FIFA Quality Pro standards. This innovation ensures optimal performance for sports applications while reducing water consumption by up to 98% annually.

Technical Superiority in Production

Leading factories employ ultraviolet (UV) stabilization technologies, extending product lifespans to 15–20 years under extreme weather conditions. Automated tufting machines achieve precision densities of 18,000 stitches per square meter, enhancing realism for lawn artificial grass products. Additionally, eco-friendly backings made from recycled latex reduce carbon footprints by 40%, aligning with global sustainability certifications like ISO 14001.

Manufacturer Comparison: Key Metrics

| Factory | Product Range | Durability (Years) | Customization Options | Annual Output (sqm) |

|---|---|---|---|---|

| TurfMaster Pro | Golf, Landscaping, Walls | 18 | 12 colors, 3 pile heights | 5,000,000 |

| GreenScape Innovations | Residential, Commercial | 15 | 8 colors, 2 textures | 3,200,000 |

| EcoTurf Solutions | Walls, Sports Fields | 20 | 15 colors, 4 patterns | 6,750,000 |

Tailored Solutions for Every Need

Factories offer specialized designs such as artificial grass for wall decor, featuring fade-resistant fibers and flame-retardant coatings. Customizable parameters include:

- Pile height variations (10mm–50mm)

- Drainage systems (permeable vs. non-permeable)

- UV protection levels (UPF 50+ to 100+)

For golf courses, factories provide low-roll putting green turf with a stimpmeter rating of 10–12, ensuring professional-grade playability.

Real-World Applications and Success Stories

A recent project by TurfMaster Pro transformed a 12,000 sqm urban rooftop into a lush recreational space using 30mm landscape grass. Key outcomes:

- 85% reduction in maintenance costs

- 50% faster installation vs. natural sod

- LEED Gold certification achieved

Eco-Conscious Manufacturing Practices

Top factories utilize closed-loop water systems and solar-powered machinery, cutting energy use by 35%. Post-consumer recycled materials constitute 60% of raw inputs, while biodegradable packaging minimizes landfill waste.

The Strategic Edge of Professional Artificial Grass Factories

Collaborating with a certified artificial grass factory guarantees access to cutting-edge R&D, bulk pricing (saving up to 25% on large orders), and warranties exceeding 10 years. Whether sourcing artificial golf turf grass for stadiums or decorative panels for architectural projects, partnering with industry leaders ensures unmatched quality and compliance.

(artificial grass factory)

FAQS on artificial grass factory

Q: What materials are used in artificial grass production at your factory?

A: Our factory uses premium UV-resistant polyethylene (PE) and polypropylene (PP) fibers, paired with eco-friendly latex backing for durability and sustainability. All materials meet international safety and environmental standards.

Q: Can your artificial golf turf grass factory customize products for specific course requirements?

A: Yes, we offer tailored solutions for pile height, density, and color to match golf course standards. Custom designs and branding options are also available upon request.

Q: How does your lawn artificial grass factory ensure product durability for outdoor use?

A: Our grass features advanced drainage systems, UV stabilization, and abrasion-resistant backing to withstand harsh weather and heavy foot traffic. Quality tests are conducted at every production stage.

Q: Do you provide installation guidelines for artificial grass for wall decor from your factory?

A: Yes, we supply detailed installation manuals and video tutorials with every order. Our team also offers remote support for complex wall decor projects.

Q: What certifications does your artificial grass factory hold for product safety?

A: Our factory is ISO 9001 and SGS certified, ensuring compliance with REACH and ASTM standards. All products are lead-free and non-toxic for residential and commercial use.

With years of expertise in artificial grass, we're dedicated to providing eco-friendly, durable, and aesthetically pleasing solutions.

Our commitment to quality and customer satisfaction shapes every blade of grass we produce,

ensuring that we not only meet, but exceed,your landscaping expectations.