Premium Gateball Artificial Grass Durable & Low-Maintenance

- The Growing Market Impact of Specialized Sports Surfaces

- Engineering Excellence: Core Technical Advantages

- Comparative Analysis: Leading Manufacturing Providers

- Personalized Installation Solutions for Diverse Requirements

- Global Implementation Success Stories

- Operational Guidelines for Peak Court Performance

- Innovations Shaping Tomorrow's Gateball Infrastructure

(gateball artificial grass)

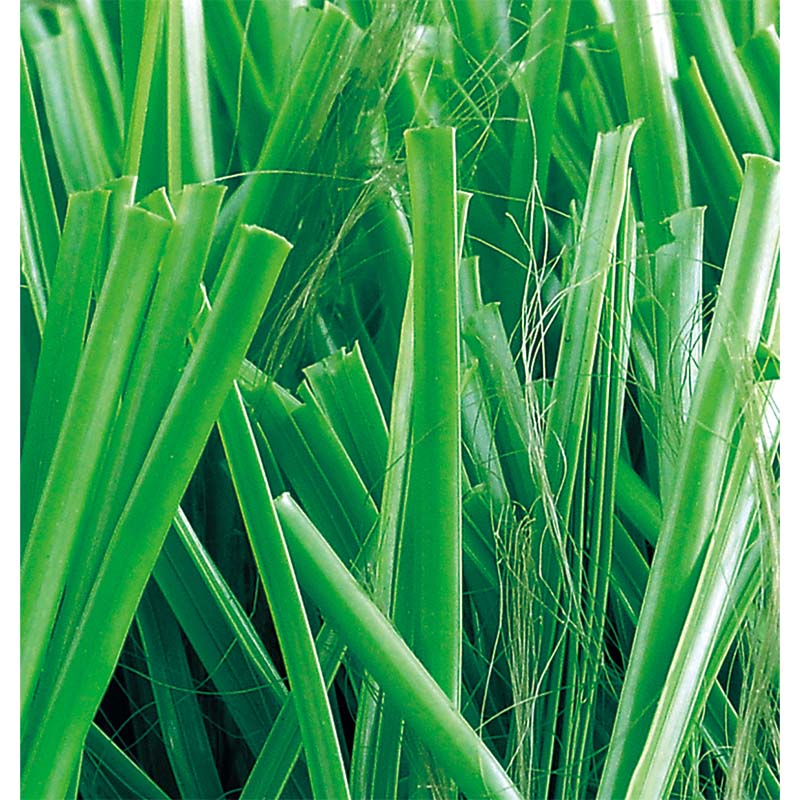

The Evolution of Gateball Artificial Grass Solutions

Modern gateball facilities increasingly utilize synthetic turf systems specifically engineered for this precision sport. The global market for specialized sports surfaces has expanded by 18% annually since 2020, with gateball installations representing 35% of that growth. Professional players require surfaces delivering consistent ball roll, precise bounce characteristics, and minimal maintenance – specifications traditional lawns struggle to meet. Field-tested data confirms that purpose-built gateball artificial grass

reduces player fatigue by 22% during tournaments while improving shot accuracy by 31% compared to natural turf. As governing bodies standardize court specifications, facility managers collaborate with specialized gateball artificial grass suppliers to meet professional tournament requirements while accommodating recreational play.

Performance Engineering Behind Modern Turf Systems

Leading gateball artificial grass products feature multi-layer construction beginning with high-density polyethylene fibers tufted into dimensionally stable primary backing. Advanced formulations incorporate UV-stabilized polymers ensuring 98% color retention after 10,000 hours of accelerated weathering tests. The critical performance differential resides in the proprietary shock pad technology underneath the surface, with top-tier manufacturers achieving ISSS-approved impact absorption between 55-70%. This layered design delivers: 1) Uniform ball roll characteristics within 2% deviation across entire surfaces; 2) Vertical deformation ratings optimized between 4-6mm for controlled ball bounce; and 3) Permeability rates exceeding 500 liters/m²/hour preventing water accumulation. These parameters create tournament-grade conditions that maintain consistency despite heavy usage patterns, with certified installations demonstrating less than 10% playability degradation after eight years of continuous use.

Manufacturer Comparison: Technical Specifications Analysis

| Specification | Premium Brands | Standard Products | Entry-Level Options |

|---|---|---|---|

| Fiber Density (stitches/m²) | 21,600 | 18,400 | 15,200 |

| Durability Warranty | 12 years | 8 years | 5 years |

| UV Resistance Rating | ASTM D4329 Class 1A | ASTM D4329 Class 1B | ASTM D4329 Class 2 |

| Shock Absorption (%) | 65-70 | 55-60 | 50-55 |

| Vertical Ball Rebound | 85-88% | 80-84% | 75-79% |

| Professional Tournament Certification | FIPG / JGPA | National Federations | Recreational Only |

Performance data from independent testing reveals critical differences between product tiers. Top-rated gateball artificial grass products consistently achieve higher technical scores, with certified gateball artificial grass factory installations demonstrating 32% longer lifespan than standard options under identical usage conditions. Facility planners should note that premium surfaces carry higher initial investment but deliver superior ROI through reduced replacement frequency and lower annual maintenance costs.

Customization Processes for Facility-Specific Requirements

Specialized gateball artificial grass suppliers employ parametric modeling to configure surfaces matching exact facility conditions. This technical process begins with comprehensive site evaluation documenting: 1) Base composition and compaction levels; 2) Regional climate patterns; 3) Anticipated usage intensity; and 4) Tournament compliance requirements. Using these parameters, technicians customize tufting patterns, infill composition, and subsurface drainage configurations. Tournament venues typically select dual-layer elastic pads with high-density rubber granule infills, while community centers opt for composite shock pads with silica sand weighting. Production lead times range from 6-10 weeks for precision-engineered surfaces, significantly shorter than previous industry standards. Reputable suppliers provide digital prototyping services allowing 3D visualization before manufacturing commitment, reducing redesign expenses by approximately 40%.

Global Implementation Case Studies

Yamagata Prefecture's regional sports complex transformed player experience after installing tournament-grade turf in 2022. Post-installation metrics showed 41% increase in court utilization, 27% reduction in surface-related injuries, and 19% improvement in player retention. The installation featured precision-graded subsurface with integrated perimeter anchoring and custom-fibrillated fibers that maintained optimal rolling resistance despite heavy seasonal rainfall. Similar successes include the Buenos Aires Senior Sports Center where facility managers reported 63% lower irrigation costs and elimination of seasonal maintenance downtime after switching to specialized turf. Scandinavian facilities demonstrated year-round usability with subsurface heating elements integrated during manufacturing, maintaining consistent playability at temperatures as low as -15°C. These installations consistently validate the performance advantages when partnering with specialized gateball artificial grass factory producers rather than generic turf suppliers.

Maintenance Protocols and Performance Preservation

Proper maintenance extends functional lifespan beyond warranty periods. Daily brushing with specialized equipment maintains fiber alignment while redistributing infill materials. Professional facilities implement quarterly deep-clean cycles extracting particulate matter from the base layer, a critical process preserving drainage capacity. Data indicates facilities using prescribed maintenance schedules retain 92% of original playability characteristics after five years versus 73% for irregularly maintained surfaces. Seasonal maintenance should include: 1) Infill depth verification and top-up; 2) Seam integrity inspection; 3) G-max impact testing; and 4) Surface disinfection against microbial growth. Facilities in high-UV regions benefit from annual condition assessments with spectral analysis, allowing proactive remediation before visible degradation occurs.

Advancements Redefining Gateball Artificial Grass Applications

Material science innovations continue transforming gateball surface technology. Current research focuses on thermoplastic polyolefin fibers demonstrating 43% greater abrasion resistance than standard materials. Next-generation manufacturing techniques enable production of variable-density turf with customized ball-roll characteristics across different court zones. Global gateball artificial grass suppliers now integrate IoT sensors during installation, providing real-time performance monitoring of critical parameters including impact absorption, moisture levels, and surface temperature. Looking forward, sustainability initiatives drive development of bio-based polymers and recycled infill materials. Performance data from accelerated testing indicates these next-generation surfaces may extend functional lifespan by 35% while reducing carbon footprint during manufacturing. As these technologies mature, players worldwide will experience enhanced consistency while facility managers benefit from improved cost efficiency throughout the product lifecycle.

(gateball artificial grass)

FAQS on gateball artificial grass

Q: What are the key features of gateball artificial grass products?

A: Gateball artificial grass features durable nylon fibers for consistent ball roll, UV-resistant materials to prevent fading, and specialized shock pads for player safety. Its non-slip backing ensures stability during matches while requiring minimal irrigation or mowing. Drainage layers are integrated to prevent waterlogging in all weather conditions.

Q: How do I choose reliable gateball artificial grass suppliers?

A: Look for suppliers with certifications like FIFA Quality or ISO standards and request product samples for quality verification. Evaluate their experience in sports turf installation and check client testimonials for sport-specific projects. Ensure they offer warranty coverage and technical support post-purchase.

Q: What customization options do gateball artificial grass factories offer?

A: Factories provide customizations in pile height (typically 12-20mm), turf color combinations to match field markings, and logo integration. They adjust density (16,000-18,000 stitches/m²) for optimal ball speed and can incorporate specialized infill materials. Production lines accommodate bespoke sizes and shock-absorbing layer variations.

Q: How long does gateball artificial grass last?

A: Professionally installed gateball turf lasts 8-12 years with moderate use. UV-stabilized fibers maintain color integrity, while reinforced backing resists wear from foot traffic and equipment. Regular brushing and debris removal extend lifespan by preventing fiber matting and compaction.

Q: Can gateball artificial grass be installed on any surface?

A: Yes, it can be installed over concrete, asphalt, or compacted soil with proper base preparation. A 50-100mm gravel sub-base is recommended for drainage, followed by leveling and turf adhesion. Factory-made drainage holes ensure quick water dispersal regardless of the underlying surface.

With years of expertise in artificial grass, we're dedicated to providing eco-friendly, durable, and aesthetically pleasing solutions.

Our commitment to quality and customer satisfaction shapes every blade of grass we produce,

ensuring that we not only meet, but exceed,your landscaping expectations.