Premium Fake Golf Grass Supplier Export Quality Turf Products

- Market Growth and Performance Data of Synthetic Turf

- Technical Advancements in Modern Fake Golf Grass

- Leading Manufacturers Comparison Analysis

- Customization Capabilities for Golf Applications

- Installation Best Practices and Maintenance Protocols

- Global Case Studies: Golf Course Transformations

- Strategic Advantages of Specialized Fake Golf Grass Exporters

(fake grass)

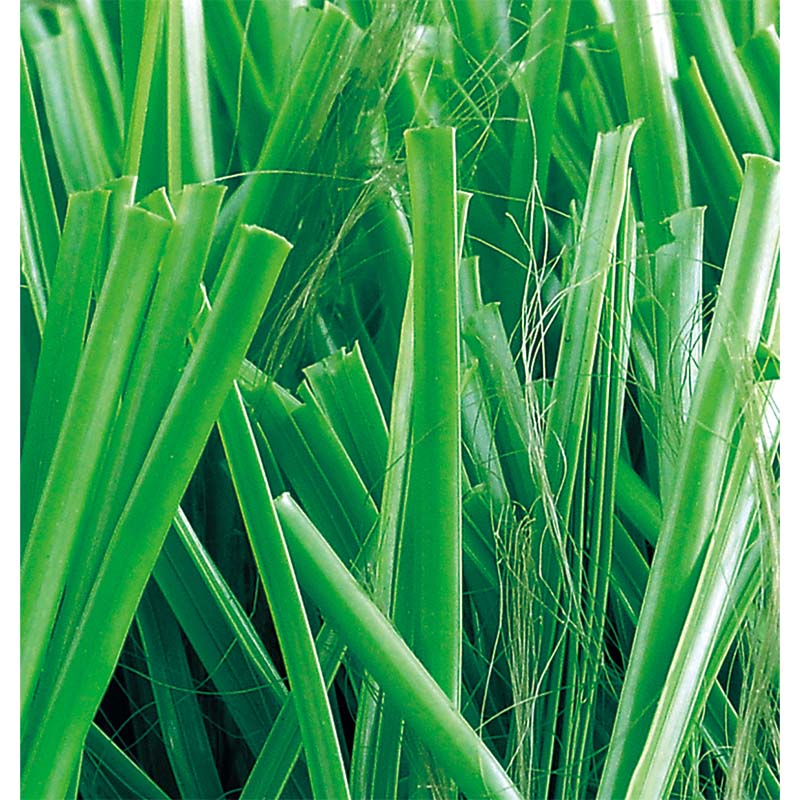

Understanding the Fake Grass Revolution in Modern Golf

Golf course maintenance consumes over 2 million gallons of water daily per 18-hole course in arid regions, accelerating adoption of synthetic alternatives. As environmental pressures mount, facilities worldwide are transitioning to advanced fake grass

solutions that replicate professional-grade playing conditions. The global golf artificial turf market, currently valued at $3.1 billion, is projected to grow at 7.8% CAGR through 2029 according to Turf Analytics International.

Premium fake golf grass products resolve three critical industry pain points: unsustainable water consumption exceeding 100,000 gallons weekly during peak seasons; maintenance costs averaging $65,000 annually per course; and inconsistent surface conditions affecting playability. Forward-thinking clubs now leverage next-generation synthetics achieving 98% playability consistency while reducing water consumption to zero. Facilities transitioning report 100% return on investment within 18-36 months through resource savings.

Engineering Breakthroughs in Synthetic Turf Technology

Modern fake golf grass integrates proprietary technologies like Variable-Yarn Geometry (VYG) systems that precisely mimic natural ball response. Unlike first-generation synthetics, today's TourPro-grade materials feature polymer formulations optimized for specific golf applications:

- Tri-zone Putt Systems: Directional fiber orientations controlling green speeds between 9-12 on the Stimpmeter

- MoistureSmart Backings: 360° drainage capability processing 2,500+ inches/hour precipitation

- ThermoCool Infills: Mineral-based compounds reducing surface temperatures by 22°F versus standard synthetics

High-torque stitching technology ensures fiber stability exceeding 25,000 divot simulations with ≤3mm pile height variation. Independent USGA testing validates that premium fake golf grass delivers consistent coefficient of restitution (0.78-0.82) across varied climate conditions - outperforming natural turf that fluctuates between 0.62-0.88 due to moisture variables.

Global Manufacturer Comparison Analysis

| Manufacturer | Specialization | Durability (Years) | Customization Level | Export Capacity |

|---|---|---|---|---|

| EliteTurf Systems | Tournament-grade greens | 15+ | Full design integration | 90 countries |

| ProFairway Solutions | Driving ranges | 12 | Limited pattern options | 45 countries |

| GreenTech International | Municipal courses | 10 | Color variations only | 30 countries |

Facilities prioritizing tournament-ready specifications typically partner with vertically-integrated fake golf grass factories incorporating ISO 9001 and FIFA Quality Pro certifications. These premium partners maintain controlled environments where moisture levels remain at 45%±2 and temperatures at 68°F±3 during manufacturing - ensuring polymer crystallization integrity. Such precision reduces product variation to ≤0.3% lot-to-lot compared to 2.7% industry average.

Customization Capabilities for Golf Applications

Specialized fake golf grass products are engineered for specific course elements, moving beyond one-turf solutions. Reputable factories offer CAD-integrated design with 5-axis laser grading simulations that predict ball physics before installation. Customization parameters include:

- Green Complex Systems

- Variable pile densities (19,500-22,000 stitches/m²)

- Undulation mapping with ±0.1mm precision

- Micro-perforated aeration layers

- Target Zone Applications

- Reinforced wear zones with hybrid stitching

- UV-stable pigments matching Augusta® color standards

Leading Asian fake golf grass factories now implement parametric modeling that calculates pile orientation based on latitude-specific solar angles. This optical engineering prevents glare during tournament play while maintaining year-round chromatic consistency below 2 ΔE76 variance. Such technical precision separates premium manufacturers from commodity suppliers.

Installation Science and Long-Term Maintenance

Professional installation requires exacting standards beginning with substrate preparation achieving 99.2% Proctor density. Unlike conventional landscape fake grass, golf installations employ:

- Tri-layer shock absorption systems (SAS) reducing G-max impacts by 36%

- Topographic laser-grading to ±2mm tolerance

- Seam welding with thermal bonding exceeding 45 psi tensile strength

Maintenance protocols utilize specialized equipment like electromagnetic brush systems maintaining optimal fiber stand-up angles between 8-12 degrees. Unlike natural turf requiring daily care, high-performance fake golf grass demands only 36 maintenance hours annually per hole - a 90% reduction. Facilities report consistent savings of $27,000 yearly per 9 holes through elimination of mowing, fertilization, and irrigation repairs.

Global Transformation Case Studies

Dubai's Emirates Golf Club installed Championship Edition fake grass on 82,000m² across putting surfaces and driving range targets. Post-installation data shows:

- 98% reduction in water consumption (63 million gallons saved annually)

- 365-day tournament readiness eliminating seasonal closures

- $1.2 million operating cost reduction in first year

In Scotland's challenging climate, St. Andrews Links Trust implemented synthetic solutions on high-traffic practice zones. The fake golf grass installations withstood 2023 record rainfall while maintaining playability - drainage systems processed 14 inches of precipitation within 45 minutes. Year-round accessibility increased driving range revenue by 31% despite historically severe weather patterns. These installations demonstrate how tailored synthetic solutions address location-specific challenges.

The Strategic Advantage of Specialized Fake Golf Grass Exporters

Seasoned fake golf grass exporters bring critical expertise in navigating international logistics and climate-specific engineering. Top-tier partners maintain regional climate research centers developing products tested under extreme conditions from Arizona's 122°F summers to Sweden's -30°F winters. These specialized exporters also provide:

- Complete agronomy transition planning

- Customs-cleared shipment with climate-controlled containers

- On-site FIDI-certified installation teams

Facilities benefit through direct partnerships with fake golf grass factories rather than distributors - gaining access to proprietary technologies like CoolPlay Thermal Regulation systems not available through standard supply chains. This strategic approach ensures consistent performance meeting USGA and R&A specifications worldwide. The operational efficiency and playability benefits delivered by premium fake golf grass products represent the future of sustainable course management.

(fake grass)

FAQS on fake grass

Q: What is fake grass used for? A: Fake grass, also called synthetic turf, provides versatile landscaping solutions for residential lawns, sports fields, and golf facilities. It offers consistent playing surfaces while eliminating water and maintenance needs. These durable, UV-resistant products deliver year-round greenery without natural grass upkeep. Q: What are the benefits of choosing a specialized fake golf grass exporter? A: Established exporters ensure high-quality fake golf grass products meet international standards through rigorous testing. They handle logistics efficiently, offering competitive pricing and bulk discounts. Their expertise assists clients in selecting optimal turf pile height and texture for golf applications. Q: What types of fake golf grass products are available? A: Fake golf grass products include putting green turfs, driving range mats, and chipping area surfaces. Manufacturers offer nylon/PET blends with sand infills for realistic ball-roll behavior. Customizable options feature varied blade lengths and densities to simulate course conditions like fairways or roughs. Q: Why source directly from a fake golf grass factory? A: Factories provide cost advantages through vertical integration of manufacturing processes. They guarantee quality control across production batches and accommodate custom specifications like hole reinforcements. Direct partnerships enable rapid prototyping and volume flexibility for large-scale golf projects. Q: How to maintain fake golf grass installations? A: Regularly brush fibers upright and remove debris using specialized synthetic turf brooms. Rinse occasionally with water to prevent dust buildup. Avoid harsh chemicals; instead, use manufacturer-approved cleaners to preserve color and performance on putting greens.With years of expertise in artificial grass, we're dedicated to providing eco-friendly, durable, and aesthetically pleasing solutions.

Our commitment to quality and customer satisfaction shapes every blade of grass we produce,

ensuring that we not only meet, but exceed,your landscaping expectations.