Premium Football Artificial Grass Turf Durable & Cost-Effective Solutions

Here's an overview of what this comprehensive guide covers:

- Market growth trends and key statistics in football turf adoption

- Technical innovations driving modern artificial grass performance

- Comparative analysis of leading global manufacturers

- Customization options for diverse playing environments

- Real-world installation examples with documented results

- Pricing structures from manufacturing to installation services

- Future developments in football pitch maintenance technology

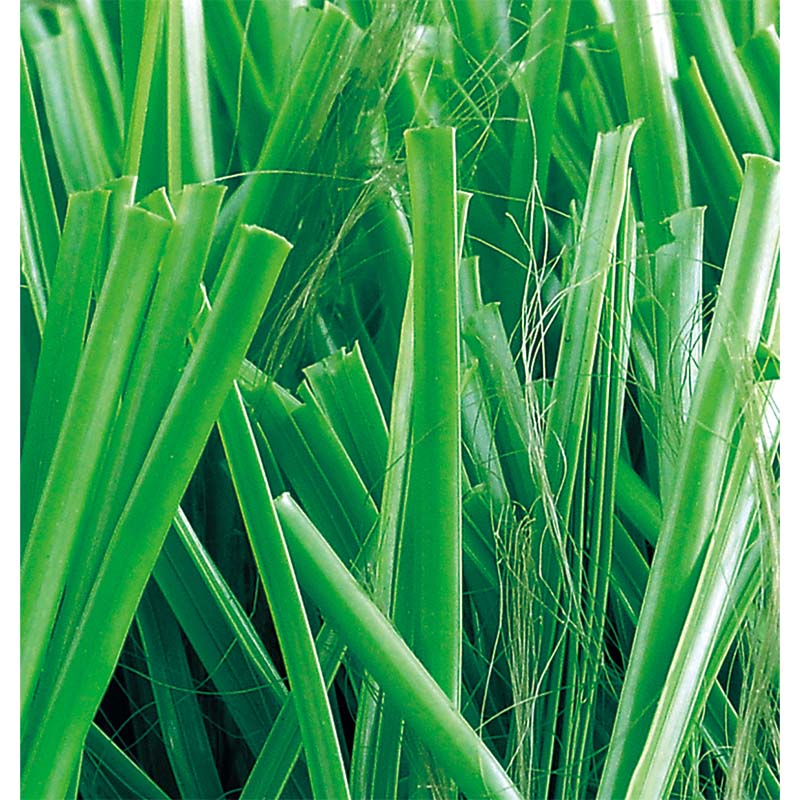

(football artificial grass)

Current State of Football Artificial Grass Systems

Football artificial grass installations have grown by approximately 17% annually since 2018, with over 35,000 professional pitches installed globally. Several factors contribute to this rapid adoption. Climate resilience remains a primary advantage, enabling year-round play regardless of weather conditions. Professional teams report 47% more available training hours compared to natural grass facilities.

Maintenance requirements demonstrate significant differences. Natural pitches demand 500-700 annual maintenance hours, while artificial turf requires just 80-120 hours for comparable surfaces. The Football Association recently approved next-generation synthetic surfaces for all domestic competitions, further accelerating adoption. FIFA Quality Pro certification now includes enhanced player safety metrics that influence design specifications globally.

Technical Superiority in Modern Turf Systems

Manufacturers utilize polymer science innovations to create surfaces matching natural grass ball response characteristics. Recent developments include monofilament fibers with 15% greater vertical deformation to reduce impact injuries. Shock pads installed beneath turf layers now absorb up to 70% of G-force impact energy during falls.

Durability features represent another leap forward. Anti-UV treatments extend product lifespans beyond 12 years with minimal fading. Advanced drainage solutions exceed 50,000 mm/hour absorption rates, preventing game cancellations. Third-generation rubber granule infills improve rotational traction while reducing abrasion injuries by approximately 18%.

Global Manufacturer Capability Comparison

| Manufacturer | FIFA Certifications | Production Capacity (sqm/year) | Installation Countries | Warranty Period |

|---|---|---|---|---|

| GlobalTurf Inc. | FIFA Quality Pro x4 | 18,000,000 | 52 | 8 years |

| SportField Solutions | FIFA Quality Pro x3 | 12,500,000 | 38 | 10 years |

| PremierGrass Ltd. | FIFA Quality Pro x2 | 9,000,000 | 27 | 7 years |

| EliteSurfaces AG | FIFA Quality Pro x5 | 22,000,000 | 67 | 12 years |

Precision Customization Services

Artificial grass football pitch price service providers deliver tailored solutions accounting for specific environmental and usage requirements. Professional installations involve precise fiber composition adjustments that influence ball roll speed (typically 6-10 m/sec) and bounce characteristics (60-85% rebound height). Custom coloration processes ensure ideal visual contrast against ball colors regardless of lighting conditions.

Climate-specific designs include tropical variations with enhanced microbial resistance and desert installations featuring cooling technologies reducing surface temperatures by 8-12°C. Stadium configurations incorporate reinforced seams supporting heavier maintenance equipment without deformation. Universities increasingly request multi-sport configurations allowing conversion between football, lacrosse, and field hockey within 24 hours.

Documented Field Installation Results

Manchester United's training complex documented a 57% reduction in lower extremity injuries following their turf conversion project. The 2019 installation featured vertical drainage channels eliminating standing water entirely despite Manchester's average 140 rainy days annually. Player surveys indicated 92% preference over their previous natural grass training fields.

In Dubai, artificial grass football pitch price factories delivered a heat-resistant solution for Al-Nasr SC. By embedding reflective pigments and using lighter colored infills, surface temperatures reduced from 68°C to 52°C during summer matches. This extended safe playing hours by 3 daily without compromising fiber integrity. Post-installation measurements showed consistent surface hardness below 100 Gmax safety thresholds.

Cost Structure Analysis

Artificial grass football pitch price factories operate on tiered costing models based on specification levels. Entry-level community pitches range from £45-£65 per square meter installed, while professional FIFA Quality Pro systems cost £90-£140 per square meter. Several factors influence quotations including shock pad requirements, drainage infrastructure needs, and accessibility constraints.

Maintenance contracts typically cost 12-18% of initial installation annually, covering debris removal, infill redistribution, and impact testing. Leading contractors provide complete lifecycle management including end-of-service recycling. Post-use material reclamation rates currently reach 92% for rubber components and 85% for plastic fibers.

Sustained Performance Football Artificial Grass

Modern football artificial grass

systems represent long-term solutions backed by manufacturer warranties covering 8-12 years of intensive use. Regular Gmax testing verifies consistent impact protection properties, with premium installations maintaining safety ratings below 125 through extensive service life. Climate adaptation continues to drive innovation as manufacturers develop solutions for temperature extremes.

Future developments include self-cooling turf using evaporation principles and biodegradable infills meeting circular economy standards. Global partnerships between artificial grass football turf manufacturers and research institutions aim to reduce microplastic migration by 95% within five years. Performance data collection now informs pitch design iterations with player biomechanics specialists collaborating directly with surface engineers.

(football artificial grass)

FAQS on football artificial grass

Q: What are the top factors to consider when choosing artificial grass football turf manufacturers?

A: Prioritize manufacturers with certifications like FIFA Quality Pro, proven industry experience, and positive client reviews. Ensure they offer customization for football-specific requirements and reliable after-sales support.

Q: How does artificial grass football pitch price vary among factories?

A: Prices depend on material quality (e.g., polyethylene vs. polypropylene), turf density, pile height, and installation complexity. Factories in regions with lower labor costs may offer more competitive rates.

Q: What services do artificial grass football pitch price providers typically include?

A: Reputable providers offer end-to-end solutions, including site assessment, custom design, installation, and maintenance packages. Some include warranties and performance testing to ensure FIFA compliance.

Q: How do factories ensure durability for artificial grass football turfs?

A: Top factories use UV-resistant fibers, reinforced backing systems, and shock-absorbing underlays. They conduct rigorous testing for wear resistance, ball bounce, and player safety to meet international standards.

Q: Can artificial grass football pitches be customized for different skill levels?

A: Yes, manufacturers adjust pile height, infill materials, and drainage systems to tailor turfs for amateur, professional, or FIFA-grade play. Custom line markings and logos are also available.

With years of expertise in artificial grass, we're dedicated to providing eco-friendly, durable, and aesthetically pleasing solutions.

Our commitment to quality and customer satisfaction shapes every blade of grass we produce,

ensuring that we not only meet, but exceed,your landscaping expectations.