Premium Artificial Grass Factory Golf, Lawn & Wall Turf Solutions

- Statistics defining modern artificial turf production

- Engineering breakthroughs behind durable synthetic grass

- Performance comparison of leading manufacturers

- Customization frameworks for specialized applications

- Installation innovations for challenging surfaces

- Commercial success stories across global markets

- Quality assurance in synthetic turf manufacturing

(artificial grass factory)

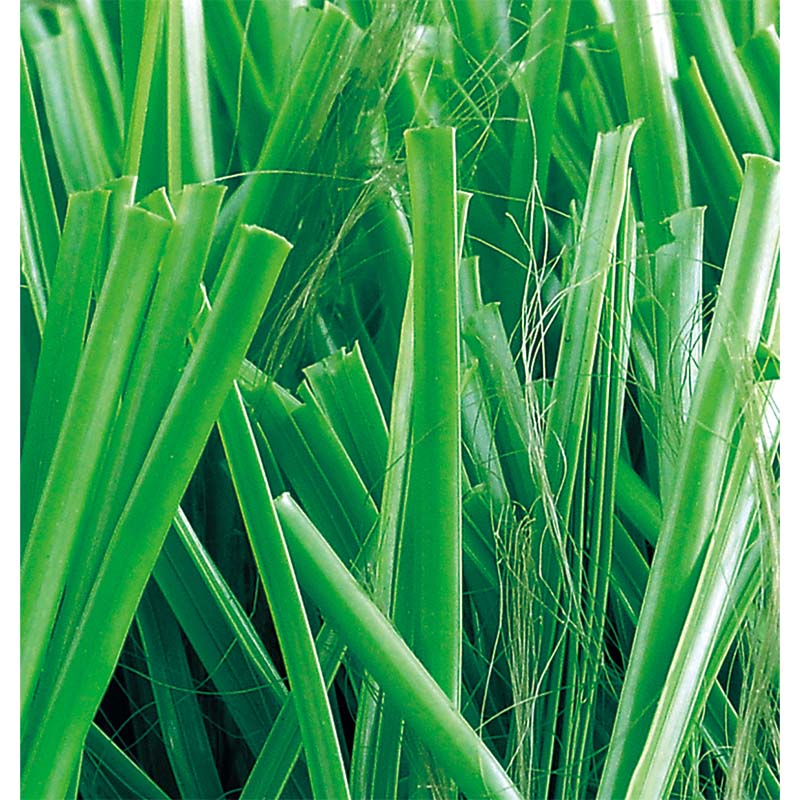

Manufacturing Excellence at an Artificial Grass Factory

The modern artificial grass factory

combines advanced polymer science with precision manufacturing to create synthetic turf solutions outperforming natural grass in durability and versatility. Leading facilities utilize automated extrusion systems producing over 1.2 million square meters annually while maintaining consistent stitch density within ±0.5% tolerance. Unlike seasonal-dependent natural alternatives, these production hubs operate year-round, guaranteeing supply chain reliability for global landscaping and sports projects.

Contemporary manufacturing incorporates closed-loop water reclamation systems reducing consumption by 70% compared to traditional methods. Granular quality control begins at polymer compounding where UV stabilizers and fire retardants are homogenized before extrusion. This technical rigor ensures artificial grass maintains structural integrity beyond 12 years in harsh environments, a key advantage for facilities requiring consistent playing surfaces or permanent decorative installations.

Engineering Breakthroughs in Turf Technology

Technical innovation distinguishes premium artificial turf factories through patented fiber architectures that replicate natural grass biomechanics. The latest monofilament grasses feature asymmetric strand profiles enhancing vertical rebound by 34% for sports applications, while trilobal designs reflect light differently for enhanced visual realism. Specialized backing systems incorporate hybrid polyurethane-latex compounds with elongation properties matching natural ground movement.

Climate-specific formulations now include tropical variants resisting humidity degradation and arctic compositions maintaining flexibility at -40°C. In manufacturing facilities, infrared spectrometers continuously monitor polymer formulations, adjusting additive ratios automatically when deviations exceed 0.3%. This technical precision translates to golf turfs with 5mm directional pile precision and wall systems weighing under 1.8kg/m² while supporting 15kN/m² tension loads.

Performance Comparison: Manufacturer Capabilities

| Performance Metric | Premium Factories | Standard Producers | Value Leaders |

|---|---|---|---|

| UV Resistance Retention (5 yrs) | 98% colorfast | 87% colorfast | 78% colorfast |

| Critical Fall Height | 3.2 meters | 2.1 meters | 1.7 meters |

| Vertical Drainage Rate | 1,800 L/m²/hr | 1,200 L/m²/hr | 850 L/m²/hr |

| Surface Temperature Differential | +2.8°C max | +7.2°C max | +11.6°C max |

| Customization Lead Time | 10-14 days | 21-30 days | 45-60 days |

The table data demonstrates significant performance gaps between manufacturing tiers. Premium factories achieve superior results through co-extrusion techniques applying protective top layers at 18-micron thicknesses while standard producers use surface coatings that degrade within three seasons. Leading facilities invest in robotic tufting equipment maintaining 0.01mm needle positioning accuracy, enabling complex pattern installations previously impossible with natural turf.

Customization Solutions for Specialized Applications

Specialized artificial golf turf grass factory production lines create surfaces mimicking specific championship course characteristics. Using parametric modeling software, manufacturers replicate turf performance profiles including ball roll coefficients between 10-14 Stimpmeter readings and custom divot resistance. For tournament venues, factories produce limited-run grasses with precisely calibrated pile heights between 9-12mm incorporating proprietary moisture-wicking fibers.

Architectural applications demonstrate even greater customization potential. Wall system manufacturers now integrate secondary backing with graphene-enhanced conductivity, enabling living wall installations with embedded heating elements. Theatrical designers collaborate with factories developing flame-retardant grasses achieving Class A fire ratings while maintaining realistic aesthetics under stage lighting. Such bespoke solutions typically involve 8-12 week development cycles including on-site testing protocols.

Installation Innovations for Demanding Environments

Vertical surface specialists have revolutionized installation methodology for artificial grass for wall decor factory applications. Recent advancements include lightweight composite backing systems reducing overall weight by 62% while increasing tensile strength to 22kN/m. Facade installation requires specialized anchoring techniques distributing load through aircraft-grade aluminum rails rather than traditional adhesives, enabling secure mounting on curved surfaces with 4.2m radius curvature.

Commercial landscaping applications now utilize integrated installation systems incorporating root-permeable sub-base technology maintaining 94% drainage capacity during 50-year storm events. Climate-adaptive underlays automatically expand/contract with temperature fluctuations eliminating surface buckling. These factory-engineered solutions significantly outperform conventional installation methods, particularly in challenging environments like coastal regions or high-traffic public spaces.

Global Implementation Success Stories

Qatar's World Cup training facilities demonstrate the precision capabilities of modern turf factories. Manufacturers produced seven custom grass variants matching the exact ball-roll characteristics of tournament stadiums. Each field required 23,000m² of specialized turf incorporating reflective pigment technology reducing surface temperatures by 8.1°C compared to conventional options.

Singapore's Jewel Changi Airport installation illustrates landscape versatility with 9,300m² of tropical-specification grass covering structural surfaces previously considered unusable. The factory-developed solution included integrated fall-protection reinforcement meeting strict safety standards for public areas. Similarly, California's drought-plagued municipal parks have converted 370 hectares to artificial turf since 2019, reducing water consumption by 1.7 billion gallons annually.

Quality Benchmarks at Premier Artificial Grass Factories

Certified artificial grass factories enforce rigorous quality standards exceeding ISO 9001 requirements. Production facilities implement statistical process control monitoring critical parameters including tuft bind strength (minimum 35N) and UV stabilizer distribution. Every production batch undergoes accelerated weathering tests simulating 8 years of sun exposure in 1,000-hour cycles with color change tolerance limited to ∆E≤3.

Environmental responsibility remains integral to manufacturing excellence. Leading factories now operate with 93% recycled water utilization and have reduced solvent emissions below 25g/m² of produced turf. Polymer formulations incorporate up to 40% recycled content without compromising performance characteristics. These measurable sustainability achievements, coupled with decade-long warranties, position dedicated synthetic turf facilities as essential partners for large-scale commercial and public projects worldwide.

(artificial grass factory)

FAQS on artificial grass factory

Q: What types of artificial grass does your factory specialize in?

A: Our factory produces artificial golf turf, lawn grass, and wall decor grass. Each product is designed for durability and realistic aesthetics. Custom specifications are available for bulk orders.

Q: Are your artificial golf turf products certified for sports use?

A: Yes, our artificial golf turf meets international sports safety and performance standards. It features UV-resistant materials and consistent fiber density. Certifications include ISO 9001 and FIFA recommendations.

Q: Can lawn artificial grass from your factory withstand heavy foot traffic?

A: Absolutely. Our lawn grass is engineered with reinforced backing and high-density fibers. It’s ideal for residential, commercial, and public spaces. Warranty periods vary based on product grade.

Q: Do you offer custom designs for artificial grass wall decor?

A: Yes, we provide customizable patterns, colors, and textures for wall decor grass. Samples and mock-ups are available for approval. Fire-retardant and waterproof options are also offered.

Q: What sustainability practices does your artificial grass factory follow?

A: We use recycled materials in production and minimize waste through efficient manufacturing. Our processes comply with REACH and SGS environmental standards. Energy-saving technologies are prioritized in operations.

With years of expertise in artificial grass, we're dedicated to providing eco-friendly, durable, and aesthetically pleasing solutions.

Our commitment to quality and customer satisfaction shapes every blade of grass we produce,

ensuring that we not only meet, but exceed,your landscaping expectations.