artificial turf roll factory

The Rise of Artificial Turf Roll Factories Innovations and Impacts

In recent years, the popularity of artificial turf has surged, driven by the increasing demand for low-maintenance, durable, and environmentally friendly landscaping solutions. As a result, artificial turf roll factories have become essential hubs of innovation, production, and sustainability. This article explores the inner workings of these factories, the technology behind artificial turf, and the broader implications for society and the environment.

Understanding Artificial Turf

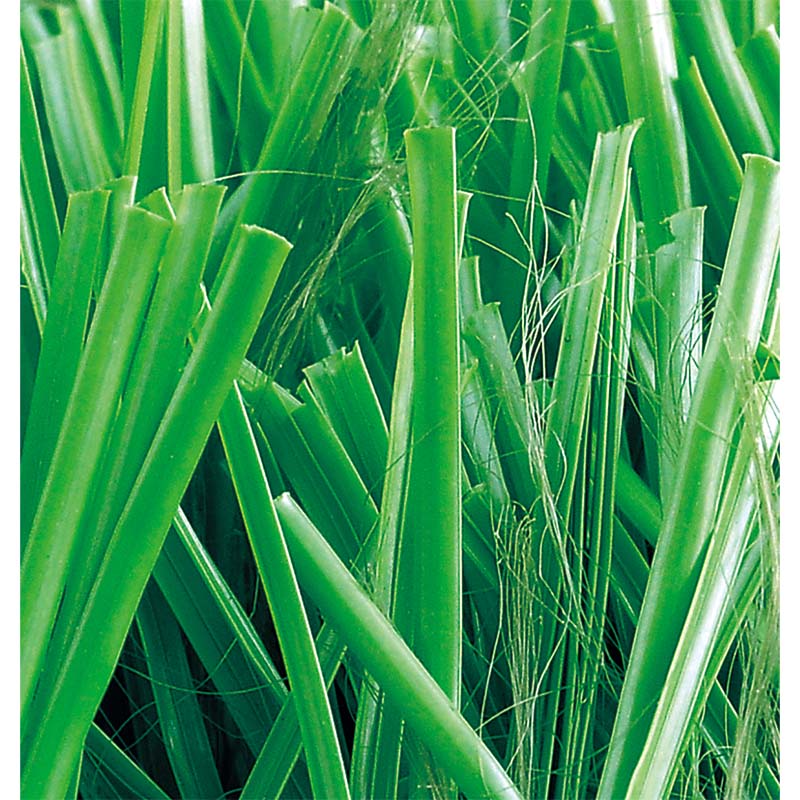

Artificial turf is typically made from synthetic fibers designed to resemble natural grass. It offers numerous advantages, including reduced water usage, lower maintenance costs, and greater durability against wear and tear. Sports fields, playgrounds, and residential lawns are just a few areas where artificial turf is utilized. With numerous styles and textures available, manufacturers can cater to varied aesthetic preferences and functional needs.

The Production Process

At the heart of an artificial turf roll factory is a complex production process that begins with the sourcing of raw materials

. The primary components of synthetic grass are polyethylene and nylon, which are processed and transformed into fibers. These fibers are tufted into a backing material, resulting in a grass-like appearance.The tufting machine plays a crucial role in this process. It inserts the fibers into a durable backing using advanced technology that allows for precise control over fiber density and height. After tufting, the product is treated with a coating that enhances its durability and UV resistance.

Once produced, the artificial turf is rolled into large cylinders, making it easier to transport and install. Factories focus on quality control at every stage of production, ensuring that the finished product meets industry standards for safety, performance, and environmental friendliness.

Innovations in Manufacturing

artificial turf roll factory

Artificial turf roll factories are at the forefront of innovation, striving to create products that are not only aesthetically pleasing but also eco-friendly. Recent advancements include the development of more sustainable materials, such as biobased plastics derived from renewable sources like corn or sugarcane. This shift not only reduces dependency on fossil fuels but also minimizes the carbon footprint associated with production.

Additionally, manufacturers are continually refining their processes to enhance efficiency and reduce waste. Techniques like precision tufting and automated cutting are implemented to ensure minimal excess material, while also reducing labor costs. By adopting these innovations, artificial turf roll factories contribute to a more sustainable industry.

Environmental and Social Implications

The rise of artificial turf roll factories has significant implications for both the environment and society. On the positive side, artificial turf can help conserve water in regions prone to drought and reduce the need for harmful pesticides and fertilizers. Moreover, synthetic grass eliminates the need for gas-powered lawn maintenance equipment, decreasing air pollution and carbon emissions.

However, there are concerns that must be addressed. Critics argue that the production and disposal of synthetic materials can lead to environmental issues. Many types of artificial turf are not biodegradable, posing challenges at the end-of-life stage. The accumulation of non-degradable products in landfills raises questions about sustainability. To combat this, manufacturers are exploring recycling initiatives to repurpose old turf into new products, thus promoting a circular economy.

Socially, artificial turf can enhance the quality of life by providing safe play areas for children and recreational spaces for communities. Nevertheless, the expansion of artificial turf in public areas has sparked debates about the loss of natural landscapes and biodiversity. Striking a balance between artificial and natural environments is essential to ensure that urban areas remain livable and vibrant.

Conclusion

Artificial turf roll factories represent a dynamic sector within the manufacturing industry, contributing to the growing trend of sustainable landscaping solutions. Through innovation, eco-friendly practices, and careful consideration of environmental impacts, these factories are shaping the future of both sports and leisure spaces. As society continues to seek sustainable alternatives to traditional landscaping, the role of artificial turf factories will only become more significant, influencing not just aesthetics but also environmental health and community well-being. The commitment to continuous improvement and sustainability will determine the long-term success of this industry in balancing human needs with ecological responsibility.

With years of expertise in artificial grass, we're dedicated to providing eco-friendly, durable, and aesthetically pleasing solutions.

Our commitment to quality and customer satisfaction shapes every blade of grass we produce,

ensuring that we not only meet, but exceed,your landscaping expectations.