Premium Synthetic Lawn Grass Durable & Low-Maintenance Solutions

- The Growing Market Impact of Synthetic Turf Solutions

- Technical Advancements in Modern Synthetic Grass Products

- Comparative Analysis of Industry-Leading Suppliers

- Customization Capabilities for Specific Applications

- Innovative Installation Methodologies

- Demonstrated Success Through Case Studies

- Future Evolution in Synthetic Turf Technology

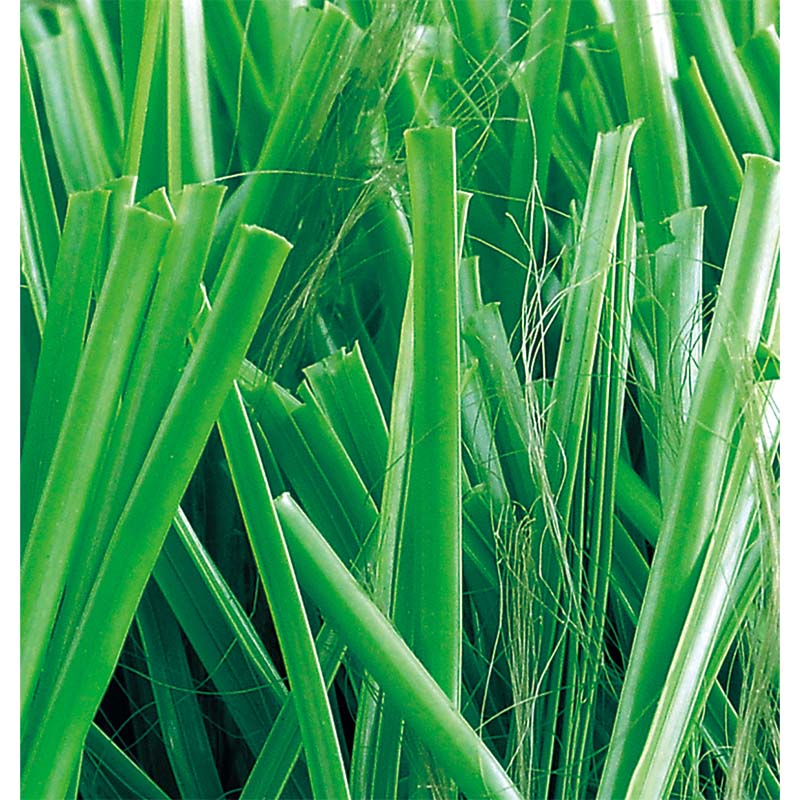

(synthetic lawn)

The Evolution and Market Impact of Synthetic Lawn Solutions

Synthetic lawn systems have revolutionized outdoor landscaping, with the global artificial grass market projected to reach $7.1 billion by 2027, expanding at a 6.8% CAGR. This growth reflects shifting environmental priorities: Residential installations conserve approximately 22,000 gallons of water annually per 1,000 sq ft compared to natural turf. Municipalities report maintenance cost reductions up to 70% after converting public spaces to synthetic alternatives.

Urban development patterns further accelerate adoption, with commercial property managers citing 35% higher tenant retention in properties featuring synthetic landscapes. Sports facilities have embraced these solutions as game-changers, enabling 3× more usage hours without recovery periods. Leading synthetic grass lawn factories now incorporate post-consumer recycled materials up to 40% across product lines, answering sustainability demands while maintaining premium aesthetics.

Technical Advancements in Synthetic Turf Manufacturing

Contemporary synthetic grass lawn products demonstrate remarkable innovation. Most advanced options feature tri-extruded polyethylene fibers with titanium dioxide coatings. This technical combination increases longevity while maintaining flexibility down to -40°F. The latest backing systems incorporate patented dual-layer woven technology that simultaneously achieves 3,000 inches/hour drainage capacity and surface stability meeting FIFA Quality Pro specifications.

Modern manufacturing techniques precisely control fiber composition. Products now include antimicrobial treatments that provide 99.9% bacterial reduction and integrated cooling technologies that decrease surface temperatures by 15°F-35°F compared to earlier generations. These innovations allow synthetic grass lawn factories to offer residential products with 12-year warranties and commercial products guaranteed for 8 years against UV degradation.

Evaluating Leading Synthetic Turf Suppliers

Selecting among synthetic grass lawn suppliers requires understanding key differentiators. Top-tier manufacturers demonstrate advanced capabilities:

| Supplier Category | Technology Implementation | Production Capacity | Customization Level | Certifications |

|---|---|---|---|---|

| Premium Manufacturers | Patented fiber technologies and cooling systems | 250,000+ sq ft daily | Full specifications customization | FIFA Quality Pro, ISO 14001 |

| Value Suppliers | Standard UV protection | 80,000-150,000 sq ft daily | Limited specification options | ISO 9001 Basic |

| Specialized Producers | Application-specific tech (e.g., shock pads) | 40,000-75,000 sq ft daily | Sport-specific solutions | World Rugby, FIH Certified |

Beyond technical specifications, certification compliance separates industry leaders. Reputable synthetic grass lawn factories maintain documented testing protocols. Premium suppliers typically conduct quarterly third-party audits with published results. This operational transparency ensures consistent quality that smaller manufacturers sometimes lack. Production capacities significantly influence customization capabilities – facilities operating 10+ manufacturing lines can accommodate specialized orders with minimum 20,000 sq ft production runs economically.

Customization Capabilities for Specialized Requirements

Modern synthetic grass lawn products offer adaptable solutions across environments. Leading suppliers provide technical adjustments including:

Fiber Technology Adjustments: Modified polymer formulas enhance resilience in temperature extremes. These advanced composites maintain structural integrity from -60°F to 180°F. Specialized applications might incorporate 13-18% nylon fibers for superior recovery characteristics critical in sports contexts.

Performance Engineering Options: Customized shock pads create impact attenuation precisely calibrated to sport requirements. The latest systems reduce critical fall height ratings by 25%-40% compared to conventional surfaces. Combined backing systems with precision needlepunch technology achieve simultaneous multi-performance objectives: Optimal water permeability exceeding 1,200 inches/hour and dimensional stability maintaining <3mm seam separation under extreme conditions.

Advanced Installation Methodologies and Standards

Proper installation determines long-term performance. Certified installers implement precision techniques:

Surface Preparation Protocol: Professional installation begins with comprehensive site evaluation. Laser grading creates 1%-2% cross-slope for drainage efficiency. The base construction phase follows strict specifications: A compacted aggregate layer minimum 4 inches with 1/4" minus gravel achieves optimal stability. Compaction density must reach 92% standard Proctor density for permanent installations.

Seaming and Finishing Technology: Advanced joining utilizes thermofusion techniques creating seamless integration. This method produces bond strengths exceeding 120 lbs/inch – 400% stronger than tape systems. Final surface tuning implements specialized power-brushing equipment that lifts fibers without damaging integrity. Installation teams certified through the Synthetic Turf Council complete rigorous training programs including 200+ supervised hours before independent project assignment.

Documented Success Through Application Case Studies

Real-world installations demonstrate performance:

Municipal Implementation: Phoenix Parks Department converted 18 acres of sports fields to synthetic surfaces, achieving:

• 65% reduction in annual maintenance expenses ($320,000 annual savings)

• Increased facility usage from 700 annual hours to 2,900 hours

• Water conservation equivalent to 21 million gallons annually

Residential Transformation: California homeowners association replaced 9 acres with premium synthetic grass lawn products:

• Eliminated $58,000 annual water, fertilizer, and maintenance costs

• Resident satisfaction scores increased from 68% to 94%

• Property values increased 5%-7% above comparable properties

Professional Sports Installation: Premier League football training ground:

• Achieved FIFA Quality Pro certification with 99% consistency rating

• Reduced player abrasion injuries by 40% compared to natural turf

• Enabled 98% annual training schedule adherence regardless of weather

Innovations Shaping the Future of Synthetic Lawn Technology

Synthetic lawn solutions continue evolving rapidly. Emerging developments include:

Biothermal-regulating fibers in advanced prototype stage demonstrate 40°F+ temperature reductions through passive hydration technology. Leading synthetic grass lawn factories are testing photovoltaic turf integration that generates 18W per sq ft/hour – sufficient to power landscape lighting systems. Material science breakthroughs include plant-based polymers derived from agricultural waste achieving full biodegradability while maintaining 10-year durability benchmarks.

Smart turf systems incorporate embedded IoT sensors monitoring surface conditions, usage patterns, and maintenance needs. These innovations transform synthetic grass lawn products into data-generating assets. Production advancements continue optimizing environmental impact – next-generation manufacturing techniques aim to reduce carbon footprint by 55% while increasing recycled content to 65%. These developments ensure synthetic solutions remain at the forefront of sustainable landscaping.

(synthetic lawn)

FAQS on synthetic lawn

Q: What are the main advantages of choosing synthetic lawn over natural grass?

A: Synthetic lawn requires zero watering, mowing, or fertilizing. It maintains perfect appearance year-round in all weather conditions. Plus, it's pet-friendly and reduces long-term maintenance costs.

Q: How do I select quality synthetic grass lawn products for my project?

A: Consider pile height, density, and UV stability ratings. Opt for materials with lead-free certifications and sufficient backing permeability. Reputable suppliers provide samples for durability testing before purchase.

Q: What should I verify when choosing synthetic grass lawn suppliers?

A: Check manufacturer certifications like ISO 9001 and warranty coverage length. Evaluate their installation support services and supply capacity. Review client testimonials specifically addressing product longevity in your climate.

Q: How do responsible synthetic grass lawn factories ensure environmental safety?

A: Ethical factories use non-toxic materials and closed-loop water recycling systems. They hold environmental certifications like ISO 14001 and implement strict chemical management protocols. Most recycle production waste into new products.

Q: What maintenance does synthetic lawn require after installation?

A: Simply rinse occasionally with water and brush periodically to maintain texture. Promptly remove organic debris to prevent mold. No specialized tools needed – standard garden hose and broom suffice for upkeep.

With years of expertise in artificial grass, we're dedicated to providing eco-friendly, durable, and aesthetically pleasing solutions.

Our commitment to quality and customer satisfaction shapes every blade of grass we produce,

ensuring that we not only meet, but exceed,your landscaping expectations.