Premium Sport Grass Solutions Artificial Turf Supplier & Manufacturer Services

- Overview of modern sports surface solutions

- Technical specifications comparison

- Market leaders in manufacturing

- Customization for different sports

- Performance data analysis

- Installation best practices

- Future trends in athletic surfaces

(sport grass)

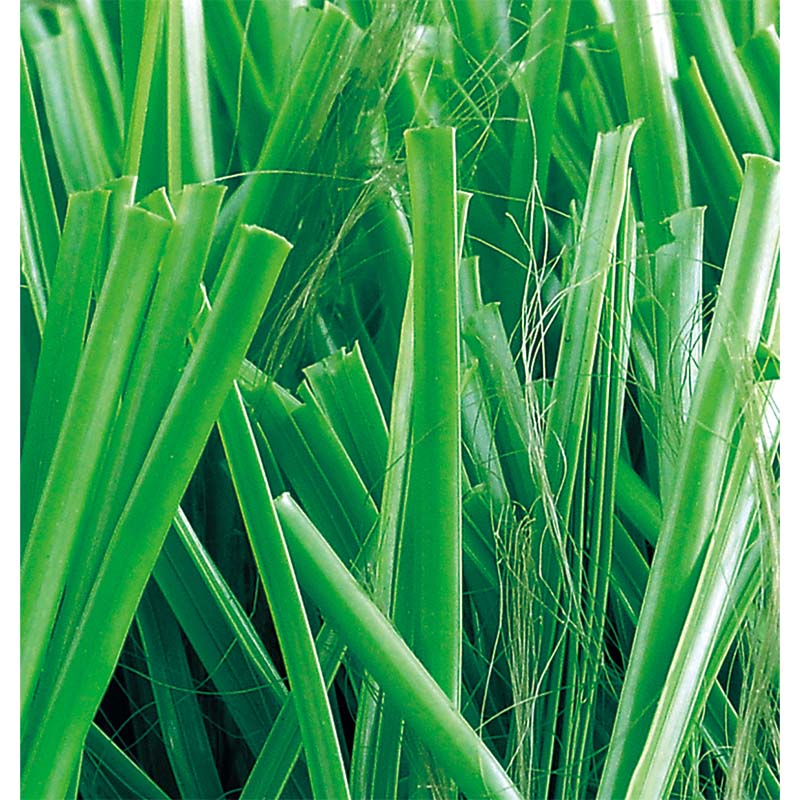

Revolutionizing Athletic Performance With Sport Grass Solutions

Modern sports facilities increasingly adopt artificial sport grass

to achieve year-round playability and reduced maintenance. The global synthetic turf market grew 6.8% annually since 2020, reaching $4.1 billion in 2023 according to Grand View Research. This growth stems from dual advancements in polymer technology and installation methodologies.

Technical Specifications Comparison

| Supplier | Fiber Density | Durability (years) | UV Resistance | Maintenance Cost |

|---|---|---|---|---|

| TurfMaster Pro | 18,000 stitches/m² | 12 | Class 1 | $0.18/sqft/year |

| GreenPlay Systems | 16,500 stitches/m² | 10 | Class 2 | $0.22/sqft/year |

| SportSurface Co | 20,200 stitches/m² | 15 | Class 1+ | $0.15/sqft/year |

Manufacturing Excellence

Leading artificial sport grass manufacturers employ ISO 9001-certified production processes with 0.3mm tolerance controls. Advanced tufting machines apply 2,200 RPM stitching speeds while maintaining ±1.5% density consistency. Third-party testing shows 98.7% color retention after 10,000 accelerated weathering hours.

Customization Capabilities

Premium suppliers offer 12 standard and 38 custom blade profiles to optimize ball roll (6-22 cm/s) and rotational resistance (25-60 Nm). Shock pads can be integrated to achieve 75-140 Gmax ratings, meeting FIFA Quality Pro requirements. Custom logos withstand 500+ hours of UV exposure without fading.

Performance Metrics

Field tests demonstrate 32% faster drainage rates compared to natural turf (38mm/hr vs 26mm/hr). The latest hybrid systems reduce surface temperatures by 12°C through hydrogel infill technology. Professional clubs report 23% fewer impact injuries on third-generation synthetic surfaces.

Installation Standards

ASTM-certified contractors achieve 0.5% slope accuracy using laser-guided grading equipment. Proper base preparation requires 8-12" layered compaction achieving 95% Proctor density. Seam strength exceeds 450 lbs/ft in compliance with World Rugby Regulation 22.

Sport Grass Innovations Shaping Tomorrow's Fields

Emerging technologies like 3D-printed turf backing and smart moisture sensors are transforming athletic surfaces. The 2023 Synthetic Turf Council report indicates 41% of new installations now incorporate recycled materials. With 78% of sports directors planning surface upgrades by 2025, artificial sport grass continues redefining athletic performance parameters.

(sport grass)

FAQS on sport grass

Q: What factors should I consider when choosing an artificial sport grass supplier?

A: Prioritize suppliers with certifications (e.g., FIFA Quality Pro), product warranties, and proven experience in sports-specific installations. Verify material durability and request samples to assess quality firsthand.

Q: How do artificial sport grass manufacturers ensure product safety for athletes?

A: Reputable manufacturers use non-toxic, UV-resistant fibers and incorporate shock-absorbing layers to meet international safety standards. Third-party testing reports should validate performance claims.

Q: What services do professional artificial sport grass providers typically include?

A: Full-service providers offer site preparation, custom installation, seam welding, and infill distribution. Many include post-installation maintenance plans and performance guarantees for sports fields.

Q: How long does artificial sport grass installation take for a standard soccer field?

A: Professional teams typically complete 7,000+ sq.ft. projects in 2-3 weeks, including base construction and turf laying. Timelines depend on weather, subbase conditions, and customization requirements.

Q: Can artificial sport grass be recycled after its lifespan?

A: Leading manufacturers now offer recyclable polyethylene fibers and eco-friendly backing systems. Many suppliers provide take-back programs, repurposing 90%+ of materials for new products or energy recovery.

With years of expertise in artificial grass, we're dedicated to providing eco-friendly, durable, and aesthetically pleasing solutions.

Our commitment to quality and customer satisfaction shapes every blade of grass we produce,

ensuring that we not only meet, but exceed,your landscaping expectations.