Affordable OEM Costs for High-Quality Artificial Lawn Solutions

Understanding OEM Costs for Artificial Lawns

The demand for artificial lawns has surged in recent years due to their low maintenance requirements and aesthetic appeal. As homeowners and businesses alike seek to enhance their green spaces without the constant upkeep of natural grass, original equipment manufacturers (OEMs) have emerged as critical players in this industry. Understanding the OEM costs associated with artificial lawns is essential for anyone considering this investment.

What Are OEM Costs?

OEM costs refer to the expenses incurred by manufacturers when producing goods that are sold under another company's brand. In the case of artificial lawns, these costs include raw materials, labor, production overheads, and logistics. The pricing strategy adopted by OEMs can greatly influence the final cost of artificial grass products on the market.

Breakdown of OEM Costs

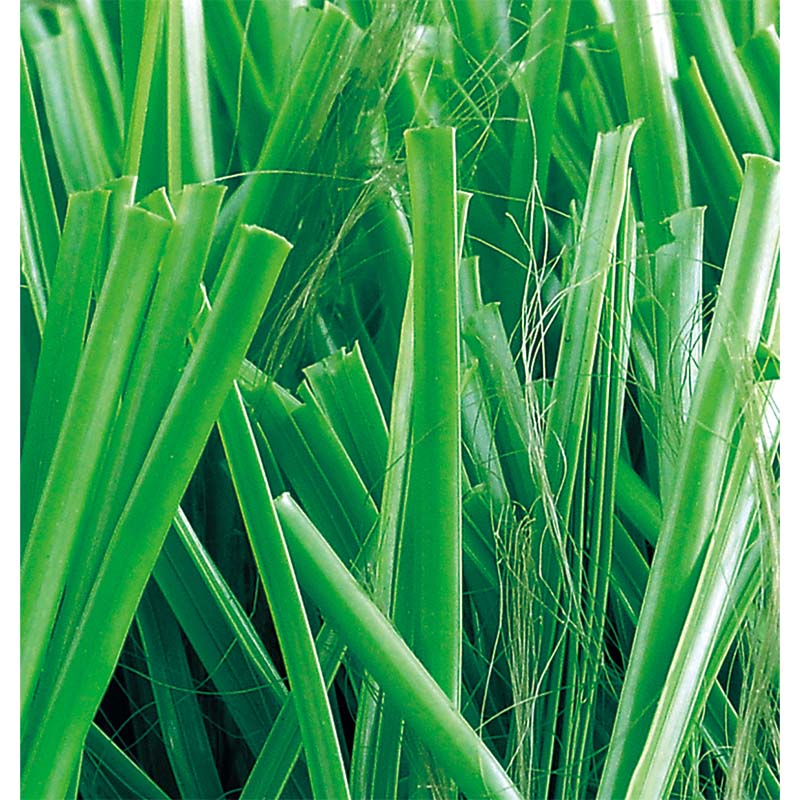

1. Raw Materials The primary material used in artificial lawns is polyethylene, polypropylene, or nylon. The cost of these synthetic fibers fluctuates based on market demand and availability. Additionally, manufacturers must consider additives for UV protection and color stabilization, which further impacts the overall material costs.

2. Production Expenses The production process involves several stages, including weaving, tufting, and coating the grass. Each stage incurs different costs related to machinery maintenance, energy consumption, and labor. High-quality manufacturing processes may require advanced technology, contributing to a higher overall OEM cost.

oem cost for artificial lawn

3. Labor Costs Skilled labor is essential in the artificial grass manufacturing process. From engineers to production workers, the wage rates vary significantly depending on the region and the expertise required. Companies may incur additional expenses if they need to invest in training to maintain high manufacturing standards.

4. Logistics and Distribution Once the artificial lawn products are manufactured, they must be distributed to retailers and customers. Shipping costs, storage fees, and handling charges can add significantly to OEM costs. Global supply chain issues may exacerbate these costs, making it crucial for OEMs to have efficient logistics management.

5. Research and Development To stay competitive, OEMs must invest in R&D to innovate and improve their products. This may include developing new materials that are more durable or environmentally friendly. As the demand for sustainable products grows, R&D costs may rise, influencing overall price points.

Pricing Strategies

To determine the final pricing of artificial lawns, OEMs must consider their entire cost structure while also factoring in market competition and consumer demand. Competitive pricing strategies, such as value-based pricing or cost-plus pricing, allow OEMs to set prices that attract customers while ensuring profitability.

Conclusion

In summary, understanding OEM costs for artificial lawns is pivotal for manufacturers and consumers alike. By analyzing the various components of these costs—raw materials, production, labor, logistics, and R&D—stakeholders can make informed decisions. As the artificial lawn market continues to evolve, OEMs who manage their costs effectively while delivering quality products will thrive in this growing industry, ultimately benefiting both consumers and the planet. Investing in artificial lawns may initially appear costly, but considering the long-term savings on maintenance and water usage, it can be a financially prudent choice that enhances the value and beauty of any property.

With years of expertise in artificial grass, we're dedicated to providing eco-friendly, durable, and aesthetically pleasing solutions.

Our commitment to quality and customer satisfaction shapes every blade of grass we produce,

ensuring that we not only meet, but exceed,your landscaping expectations.