Indoor Synthetic Turf Manufacturing Facility for High-Quality Artificial Grass Production and Innovation

The Rise of Indoor Synthetic Turf Factories

In recent years, the demand for synthetic turf has surged, driven by the increasing popularity of indoor sports and recreational activities. This trend has given rise to a new phenomenon in the manufacturing landscape indoor synthetic turf factories. These facilities are reshaping how we think about sports surfaces, offering numerous advantages in terms of usability, safety, and maintenance.

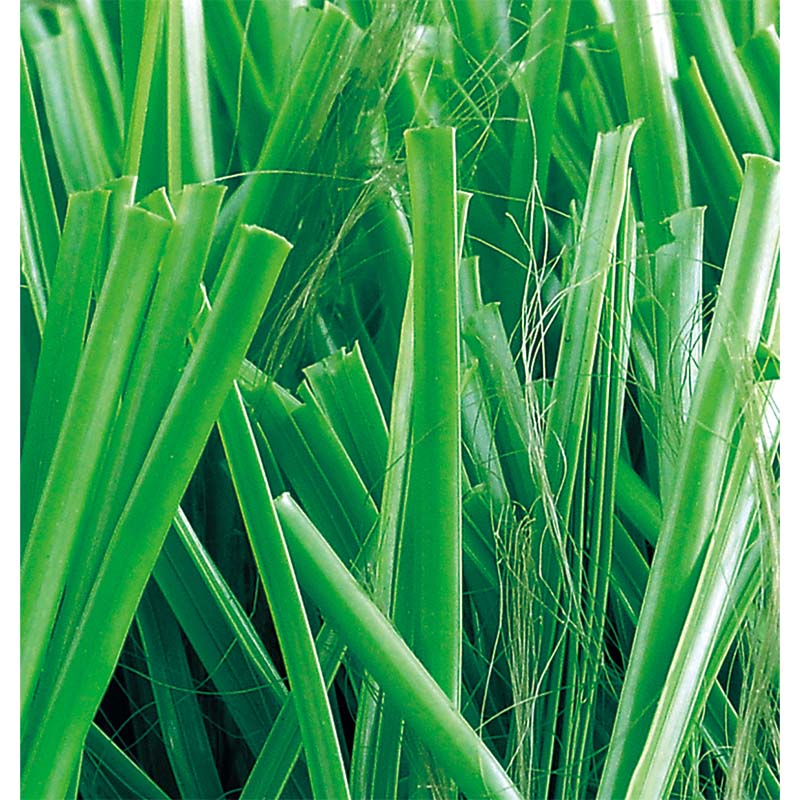

Evolution of Synthetic Turf

Synthetic turf has come a long way since its introduction in the 1960s. Initially met with skepticism, modern synthetic grass has evolved into a highly durable and visually appealing alternative to natural grass. It's designed to mimic the look and feel of natural turf while offering consistent performance year-round. This makes it particularly attractive for indoor environments where natural sunlight is limited, such as indoor sports complexes, gyms, and recreational centers.

Advantages of Indoor Synthetic Turf

One of the primary benefits of indoor synthetic turf is its versatility. It can be used for a variety of sports, including soccer, football, tennis, and even golf. Indoor synthetic turf facilities allow for year-round training and competition, undeterred by weather conditions. Athletes can practice their skills, coaches can conduct training sessions, and teams can hold games regardless of the season.

Safety is another key advantage of synthetic turf. Modern products are designed with safety in mind, featuring shock-absorbing materials that reduce the risk of injuries. This is especially critical for indoor environments, where athletes are often competing at high intensity in confined spaces. Furthermore, synthetic turf is typically more resistant to wear and tear than natural grass, which means it can withstand heavy foot traffic and rigorous play without degrading.

indoor synthetic turf factory

Cost-Effectiveness and Maintenance

Maintenance costs for synthetic turf are significantly lower than for natural grass. Indoor synthetic turf requires minimal upkeep; it doesn't need watering, mowing, or fertilization, resulting in savings on utilities and maintenance labor. Moreover, synthetic surfaces remain green and vibrant throughout the year, providing aesthetic value without the seasonal browning that natural grass experiences under indoor conditions.

Indoor synthetic turf factories are also increasingly employing eco-friendly production methods, utilizing recycled materials and non-toxic infill options. This focus on sustainability helps to mitigate the environmental impact traditionally associated with artificial surfaces and resonates well with the growing consumer consciousness regarding ecological issues.

Technological Advancements

Technological advancements are driving innovation in synthetic turf production. Manufacturers are creating more realistic grass blades that mimic the texture and feel of natural grass, making the experience more authentic for athletes. Additionally, enhanced drainage systems are being integrated into the turf design to prevent water pooling and enhance user experience during play.

Conclusion

Indoor synthetic turf factories are at the forefront of a sporting revolution, transforming how we approach indoor athletic spaces. With their countless benefits—ranging from versatility and safety to low maintenance costs and sustainability—these factories are paving the way for a new era in sports facilities. As indoor sports continue to gain traction, the role of synthetic turf will undoubtedly expand, providing athletes with a consistent and safe playing surface year-round. This paradigm shift in sports management and facility design invites not only better performance but also a healthier and more engaged community of sports enthusiasts.

With years of expertise in artificial grass, we're dedicated to providing eco-friendly, durable, and aesthetically pleasing solutions.

Our commitment to quality and customer satisfaction shapes every blade of grass we produce,

ensuring that we not only meet, but exceed,your landscaping expectations.