Exploring the Manufacturing Process of Indoor Artificial Grass in Modern Factories Today

The Rise of Indoor Artificial Grass Factories A Green Revolution

In recent years, the demand for artificial grass has surged, fueled by a growing awareness of environmental sustainability and the need for versatile landscaping solutions. Among the various applications, indoor artificial grass has gained notable popularity among businesses, schools, and homeowners, leading to the establishment of specialized indoor artificial grass factories. This article delves into the significance of these factories, their production processes, and their impact on various sectors.

Understanding Indoor Artificial Grass

Indoor artificial grass is designed specifically for indoor applications, offering a vibrant and maintenance-free alternative to natural grass. Its versatility makes it suitable for various uses, including residential décor, commercial spaces, sports facilities, and educational institutions. The unique features of indoor artificial grass include durability, aesthetic appeal, and safety, making it an ideal choice for places with high foot traffic.

The Emergence of Indoor Artificial Grass Factories

As the market for indoor artificial grass expands, factories dedicated to its production have proliferated. These manufacturing facilities typically employ advanced technologies to ensure the highest quality and performance of their products. The production process generally involves several steps the selection of materials, weaving or tufting techniques, and post-production treatments.

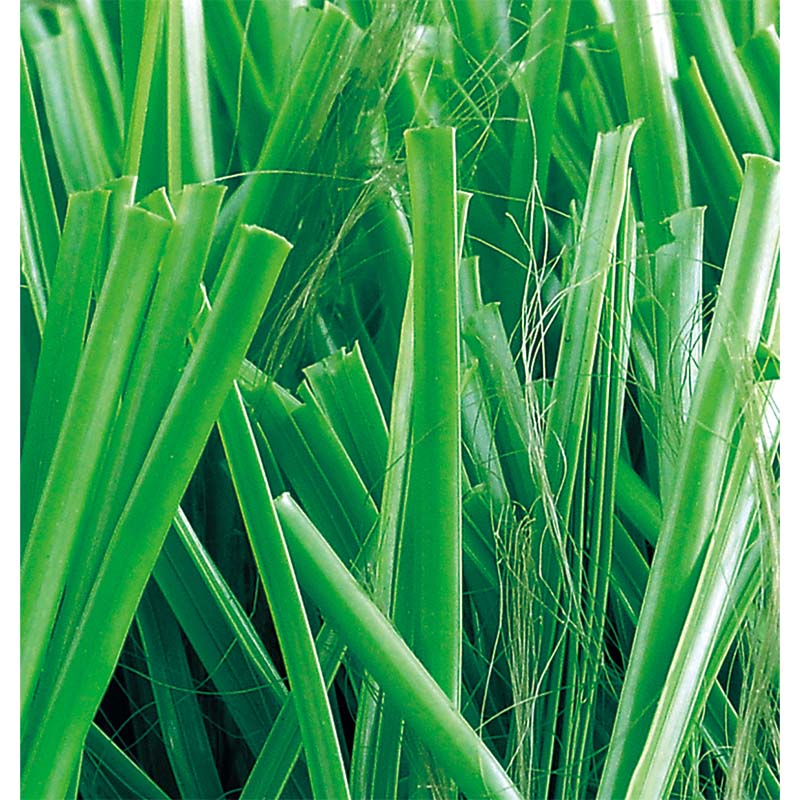

The primary materials used in artificial grass production are polyethylene, polypropylene, and nylon. These synthetic fibers are chosen for their durability and resilience, ensuring that the grass maintains its appearance and functionality over time. Cutting-edge weaving and tufting technologies enable factories to create grass with varying pile heights, densities, and colors, catering to a wide range of consumer preferences.

Environmental Considerations

indoor artificial grass factories

Indoor artificial grass factories are at the forefront of the green revolution, contributing to sustainability efforts in several ways. First and foremost, the use of artificial grass eliminates the need for chemicals associated with natural grass maintenance, such as fertilizers and pesticides, thereby reducing environmental pollutants. Additionally, indoor artificial grass does not require water for upkeep, helping to conserve precious resources in an era of increasing water scarcity.

Many modern factories are also implementing eco-friendly practices within their operations. From using recycled materials in production to minimizing waste and energy consumption, these facilities are focusing on reducing their carbon footprint. Some companies even offer take-back programs, where old artificial grass can be recycled into new products, promoting a circular economy.

Applications Across Various Sectors

The applications of indoor artificial grass are diverse and expanding. In residential settings, homeowners use it to create cozy, green environments in basements, sunrooms, or children's play areas. In commercial spaces, businesses utilize artificial grass to enhance branding and customer experience, transforming areas like showrooms, restaurants, and offices into lively, welcoming spaces.

Schools and educational institutions are also recognizing the benefits of indoor artificial grass. It provides a safe and resilient surface for physical activities, while also serving as a unique aesthetic element in classrooms and common areas. Furthermore, artificial grass can be used in therapy and rehabilitation settings, offering a soothing environment that can aid in the healing process.

Conclusion

Indoor artificial grass factories represent a fusion of innovation and sustainability, transforming the way we think about landscaping and indoor environments. As technology advances and consumer preferences evolve, these factories will likely continue to play a crucial role in meeting the growing demand for synthetic solutions. By emphasizing quality, environmental responsibility, and versatility, the indoor artificial grass industry is paving the way for a greener, more sustainable future.

With years of expertise in artificial grass, we're dedicated to providing eco-friendly, durable, and aesthetically pleasing solutions.

Our commitment to quality and customer satisfaction shapes every blade of grass we produce,

ensuring that we not only meet, but exceed,your landscaping expectations.