base for artificial grass manufacturers

Base for Artificial Grass Manufacturers Ensuring Quality and Performance

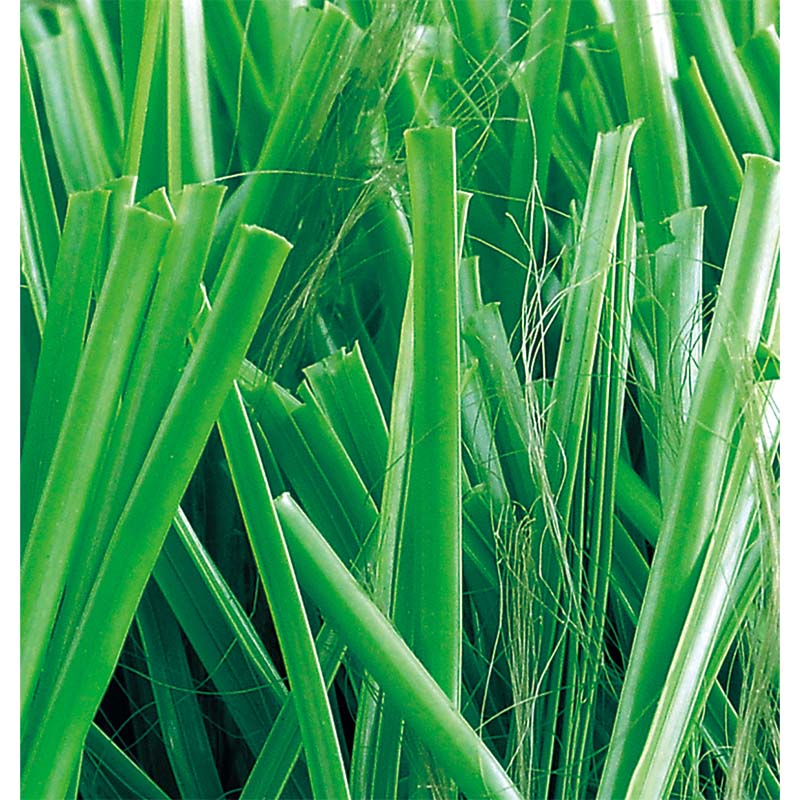

The growth of the artificial grass industry has been significant over the past few decades, driven by a rising demand for low-maintenance landscaping solutions and the desire for sustainable alternatives to traditional grass. For manufacturers of artificial grass, the quality of the base materials is pivotal, as it directly influences the product's performance, durability, and overall customer satisfaction.

A robust base for artificial grass typically consists of a combination of materials that provide excellent drainage, stability, and support for the synthetic fibers. One of the most important aspects of manufacturing artificial grass is the selection of the right sub-base, which often includes crushed stone, gravel, or sand. These materials are crucial in creating an even foundation, ensuring that the grass remains level and does not develop unsightly bumps or depressions over time.

In addition to the choice of sub-base materials, manufacturers must consider the installation process. Proper installation techniques are vital for the longevity of artificial grass. This involves compacting the sub-base meticulously to avoid any shifting or settling that could compromise the grass's integrity. A well-prepared base can significantly enhance the lifespan of the artificial grass, allowing it to withstand heavy foot traffic, extreme weather conditions, and other stresses.

base for artificial grass manufacturers

Furthermore, drainage is a critical factor to keep in mind. A well-designed base should facilitate effective water runoff, preventing puddles and waterlogging that can lead to mold growth and degradation of the grass fibers. Incorporating a permeable base layer can help achieve this goal, ensuring that water drains appropriately and the area remains dry and safe for use.

Manufacturers also need to pay attention to the environmental aspects of their base materials. As sustainability becomes an increasingly important consideration for consumers, using eco-friendly materials in the production of artificial grass is becoming a regulatory and marketing necessity. Implementing recycled materials or sourcing locally can reduce the environmental impact and appeal to eco-conscious consumers.

In conclusion, the base for artificial grass manufacturers is fundamental for the product’s quality and performance. By choosing appropriate sub-base materials, ensuring proper installation, addressing drainage, and considering sustainability, manufacturers can produce high-quality artificial grass that meets the needs and expectations of their customers. As the industry continues to evolve, staying ahead of these standards will not only enhance product offerings but also strengthen the manufacturer’s reputation in a competitive market. Therefore, investing time and resources into the base materials and techniques is essential for long-term success and customer satisfaction in the artificial grass manufacturing sector.

With years of expertise in artificial grass, we're dedicated to providing eco-friendly, durable, and aesthetically pleasing solutions.

Our commitment to quality and customer satisfaction shapes every blade of grass we produce,

ensuring that we not only meet, but exceed,your landscaping expectations.