Artificial Turf Soccer Ball Manufacturing Facility Overview and Insights

The Revolution of Artificial Grass Soccer Balls A Look Inside the Factory

In recent years, the sports industry has witnessed a significant transformation in the materials used for athletic equipment. One of the most notable advancements is the introduction of artificial grass soccer balls, which are increasingly popular among players and manufacturers alike. This article explores the intricacies of producing these innovative products within a modern factory setting, highlighting the benefits, processes, and future potential of artificial grass soccer balls.

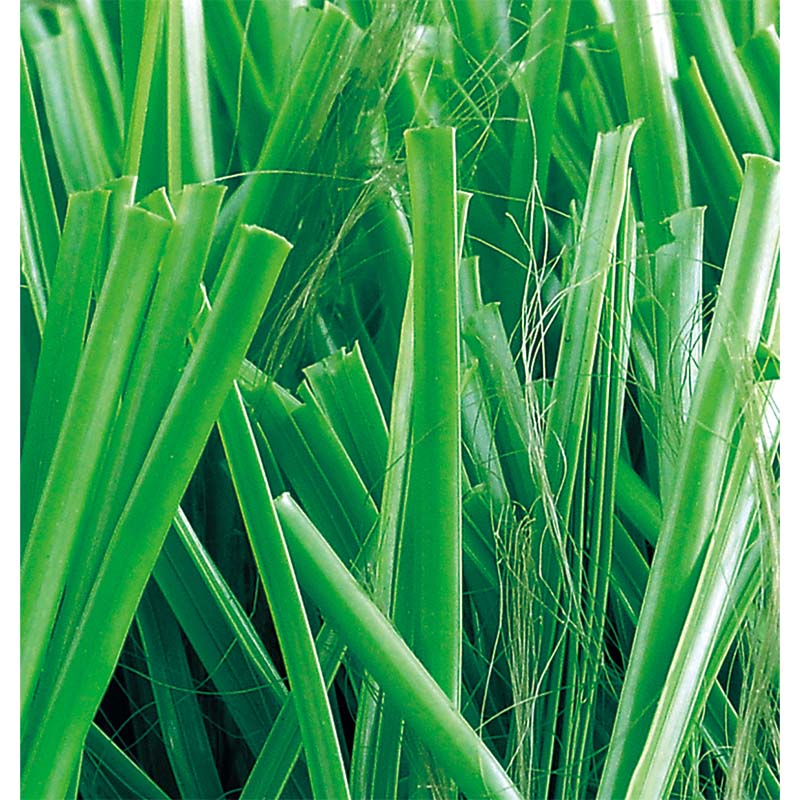

The Rise of Artificial Grass in Soccer

The move towards artificial grass in soccer fields has been driven by several factors, including durability, reduced maintenance costs, and the ability to play in various weather conditions. As a result, the demand for equipment that complements this new playing surface has surged. Enter the artificial grass soccer ball—a product specifically designed to perform optimally on synthetic turf. This innovative ball offers enhanced durability, performance, and consistency, making it ideal for both amateur and professional players.

Designing the Perfect Soccer Ball

Creating an artificial grass soccer ball begins with intricate design work. Engineers and designers collaborate to develop a ball that meets the high standards demanded by players. They consider factors such as weight, bounce, surface texture, and aerodynamics. Advanced computer simulations and prototypes are used to test various designs before final production. The goal is to ensure that the ball performs well on artificial surfaces, keeping in mind elements like grip and control.

Material Selection

The choice of materials is crucial in manufacturing artificial grass soccer balls. Manufacturers typically opt for high-quality synthetic materials, such as thermoplastic polyurethane (TPU) and ethylene vinyl acetate (EVA). These materials provide greater durability and performance, resisting wear and tear from the abrasive nature of artificial grass. The outer layer is designed to be water-resistant and UV-stabilized, which helps maintain the ball's shape and color over time.

The Production Process

artificial grass soccer ball factory

The production of artificial grass soccer balls is a multi-step process that takes place in specialized factories

.1. Cutting and Shaping The first step involves cutting the material into specific panels that will form the outer shell of the ball. These panels are often shaped using high-precision cutting machines to ensure consistency.

2. Lamination After the panels are cut, they undergo a lamination process where layers are fused together. This step adds strength and durability to the ball, ensuring it can withstand the demands of play on artificial surfaces.

3. Assembly The next step is the assembly of the balls. Skilled workers or machines stitch or glue the panels together, carefully ensuring a tight seal that helps maintain air pressure and shape.

4. Inflation and Testing Once assembled, each ball is inflated to the required pressure and tested for performance. This includes checking for consistency in shape, weight, and bounce. Any balls that do not meet specifications are discarded or reworked.

5. Quality Control Rigorous quality control measures ensure that only the best products reach consumers. This includes final inspections and testing against industry standards, ensuring that the balls perform as expected on artificial grass.

Future Prospects

The future of artificial grass soccer balls seems promising as manufacturers continue to innovate and improve their products. Advances in technology may lead to even lighter and more durable materials, enhancing performance further. Additionally, with the growing popularity of artificial grass fields worldwide, the market for high-quality soccer balls designed for these surfaces is likely to expand even more.

In conclusion, the production of artificial grass soccer balls is an intricate process that combines innovative design, material science, and rigorous quality control. As the demand for synthetic surfaces increases, so too will the technology and expertise required to produce top-performing soccer balls. This advancement not only benefits players but also marks a significant step forward in the evolution of the sport.

With years of expertise in artificial grass, we're dedicated to providing eco-friendly, durable, and aesthetically pleasing solutions.

Our commitment to quality and customer satisfaction shapes every blade of grass we produce,

ensuring that we not only meet, but exceed,your landscaping expectations.